Structural Ceramics for Measurement Devices

Sensitive sensor and measurement technology must function reliably in its process environment even under extreme operating conditions. Technical ceramics from CeramTec ensure durable function and precise measurement results.

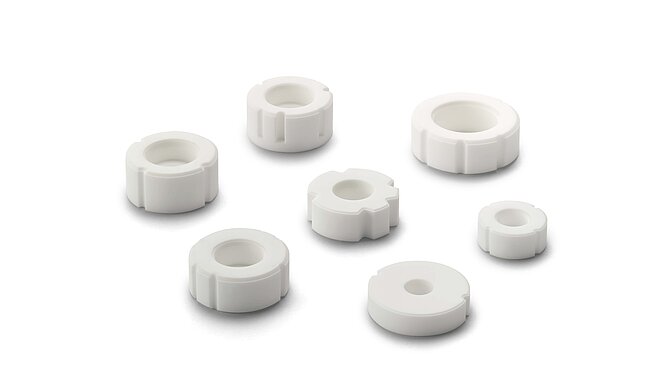

With a variety of over 40 structural ceramics materials CeramTec can manufacture ceramic components for individual customer requirements.

It all begins with Silicate ceramics, which are the most traditional of all advanced ceramics. Oxide ceramics like Aluminum Oxide in various purity levels and Zirconium Oxide are manufactured in both low and high volumes.

Non-oxide ceramics like Silicon Carbide, Silicon Nitride and Aluminum Nitride are available in large scales as well. As this is only a selection of all available ceramic materials at CeramTec, in the end we can help determine a suitable material and design for most shapes and sizes together – all based on the customer‘s requirements.

Challenges like high temperature, abrasion are easy to solve with ceramic material. The higher hardness in comparison to metal is also a real benefit. CeramTec´s high variation of prodution capabilities include dry and isostatic pressing, extrusion, 3D printing, tape casting, injection moulding, metallisation, lasering and stamping to meet individual applications needs.

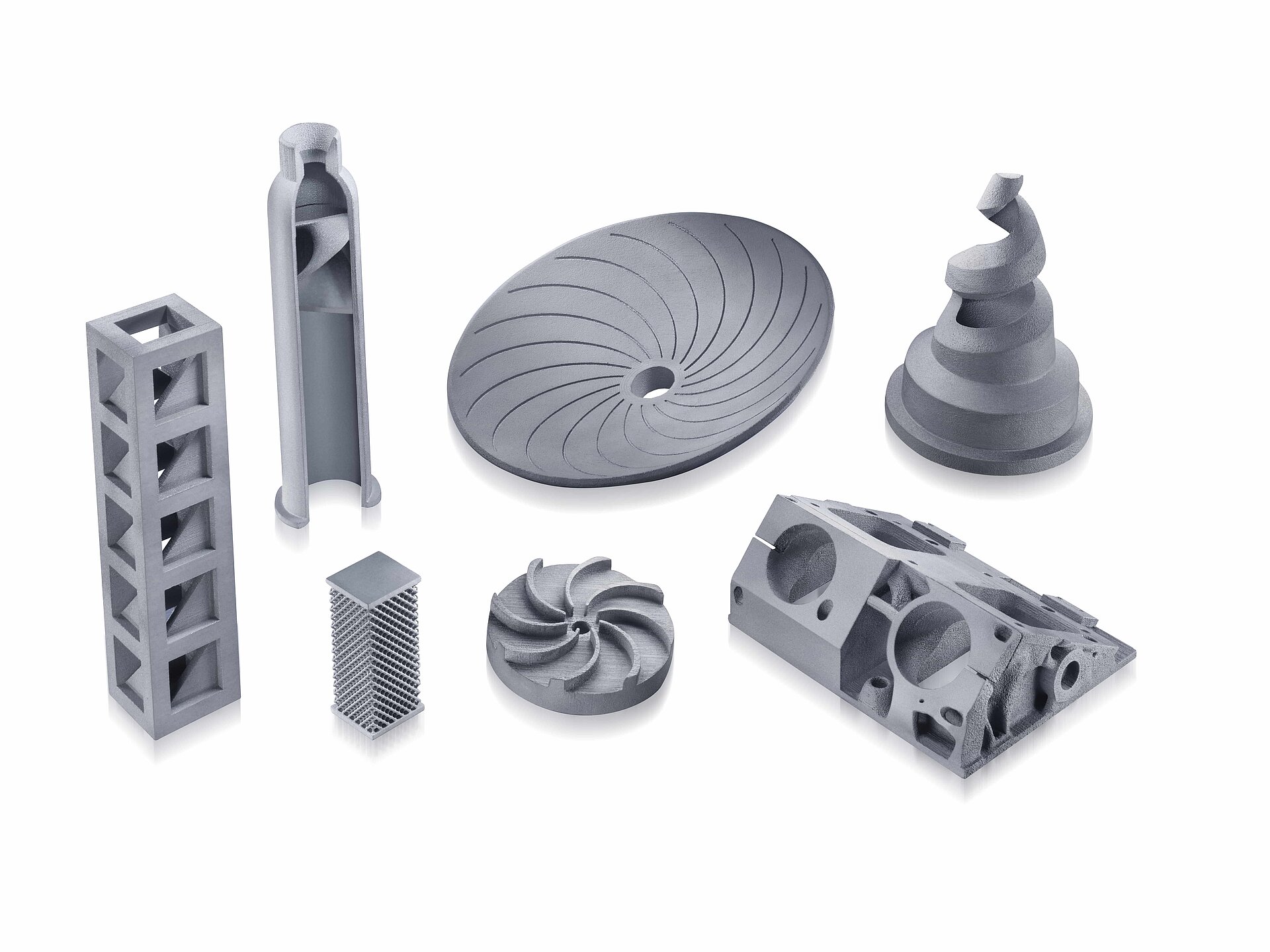

ROCAR® 3D Printing

CeramTec´s 3D printing of silicon carbide is a real game changer in the world of advanced ceramic solutions. This technology allows us maximum design variety combined with time and cost savings alongside optimal product quality.

CeramTec’s additive manufacturing specialists draw on their comprehensive expertise in ceramics to support you in the implementation of your projects. From the evaluation of data to the optimization of production – from single-batch customization to small-batch production.