Thermal Management with Ceramic Heat Sinks

At CeramTec, we develop innovative solutions for the thermal management of high-performance electronics, photovoltaics, LEDs and other applications. Our CeramCool® ceramic heat sinks made of aluminium oxide and aluminium nitride combine maximum thermal conductivity with electrical insulation, chemical resistance, corrosion resistance and numerous other strengths. How can performance be maximised when heat is no longer a limiting factor? With CeramCool® we create the basis for more efficient, more durable and more reliable systems - even under extreme conditions.

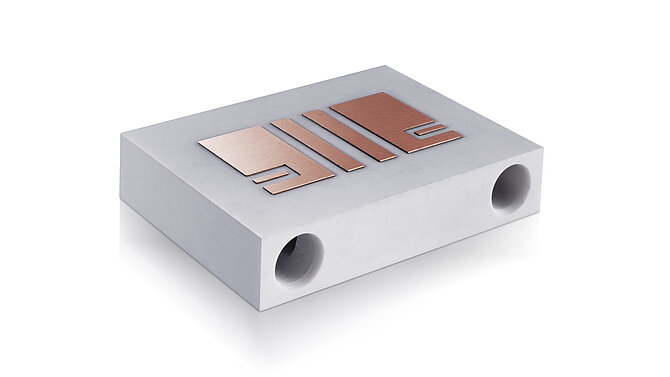

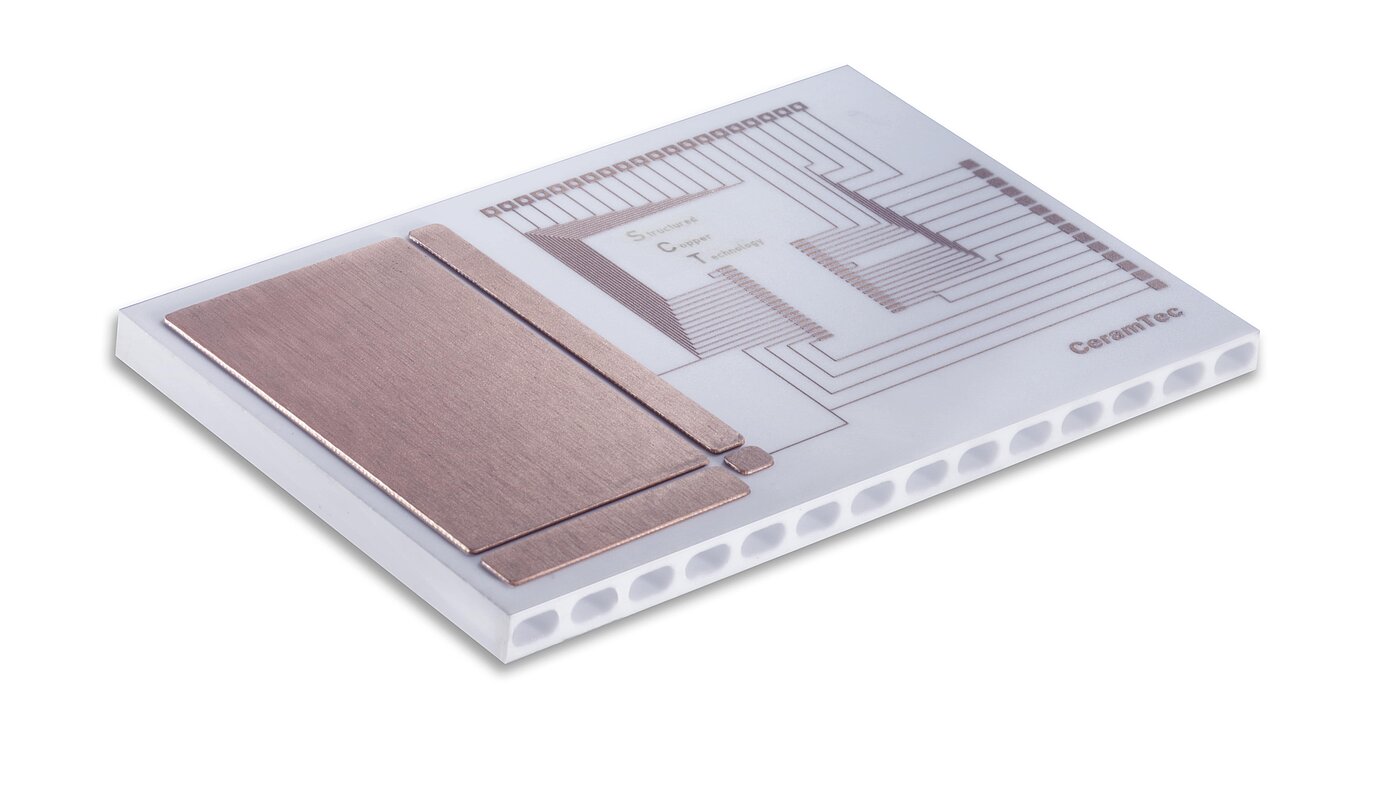

PCB & Heat Sink effectively combined

CeramCool® heat sinks are an effective combination of PCB and heat sink for the safe cooling of thermally sensitive components and circuits. They enable direct and permanent connection of components and are ideal for thermal management and cooling of power-intensive circuits in high performance electronics, high power LEDs or photovoltaic systems.

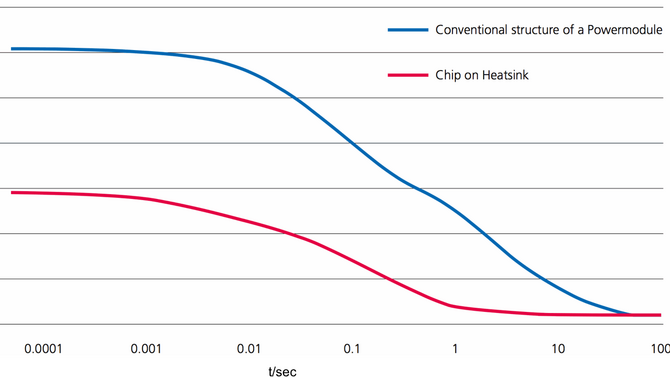

Chip-on-heatsink technology eliminates the need for additional layers and thermal barriers required in traditional designs. In addition to reducing thermal resistance, this also reduces the number of components and potential sources of failure in the overall system. This has a positive impact on assembly time and ultimately system cost. When it comes to innovative thermal management with ceramic heatsinks, the following applies "Keep it simple" - a simplified system design optimises heat dissipation.

The ceramic materials used are Rubalit® aluminum oxide and Alunit® aluminum nitride, which can be provided with various metallisations and conductive path structures, if required also three-dimensionally and "around the edge". With chip-on-heatsink, CeramTec has also developed a process that enables optimal thermal coupling to the cooling medium.

SiC Power Module with AlN Ceramic Cooler

Together with the Fraunhofer Institute for Integrated Systems and Device Technology (IISB) in Erlangen, we have developed innovative cooling solutions for the power electronics of a drive converter. Our SiC power module is primarily used where low thermal impedance, high inductivity and high power density (with low weight) are required.