A new Identity for CeramTec's Machining Solutions

CeramTec now operates its machining activities under the name SPK by CeramTec. With the revival of the traditional SPK brand, CeramTec is also expanding its range of machining solutions. Find out what SPK is all about, why CeramTec is reviving the SPK name for its machining activities and what other machining solutions CeramTec offers under SPK.

It all began over 70 years ago with the founding of Südplastik Gummi- und Kunststoff-Verarbeitung GmbH in Plochingen in the early 1950s. The company's name was abbreviated to SPK and its brand name was also SPK.

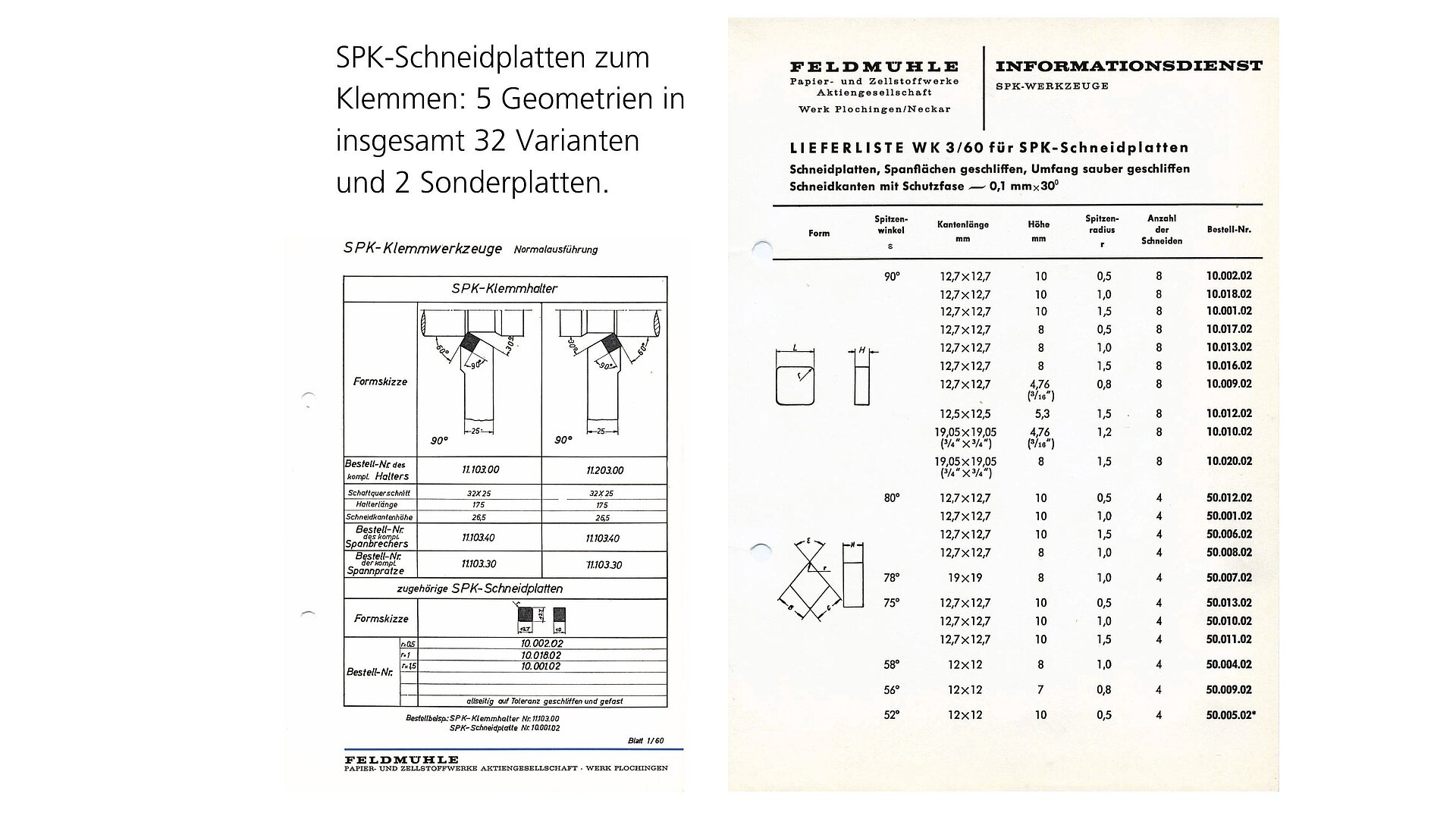

As a pioneer, the then SPK introduced cutting inserts and cutting tool for machining cast iron materials. It began with a small range of five cutting insert geometries in a total of 32 different variants, which consisted of different corner radii and chamfer designs. The cutting material was an oxide ceramic with the designation RK10.

The internationally recognized name SPK-Werkzeuge was shaped by the activities of Feldmühle AG, which SPK acquired in 1954. In a further development, the SPK brand was given the logo with the Feldmühle trademark - the Feldmühle Kringel.

Thereafter, SPK experienced further important stages with an unchanged appearance: in 1991, Feldmühle AG spun off its ceramics activities into Cerasiv GmbH, which was sold to Metallgesellschaft AG a year later. In 1996, Metallgesellschaft AG merged Cerasiv GmbH and Höchst CeramTec AG under its roof to form today's CeramTec. CeramTec also continued to use the SPK brand for its machining activities in unchanged form until 2005. In the following years, SPK was continued in a reserved role until today.

The traditional SPK brand is now more than 70 years old. In keeping with this tradition, CeramTec is reviving the name and registered trademark SPK for its machining activities under the name SPK by CeramTec. With this move, CeramTec is emphasizing the importance of its Machining division as a strategic business area, which will be consistently expanded and thus significantly strengthened by the addition of further machining areas for hard materials and HRSA materials.

What does SPK stand for today?

The traditional SPK brand stands for a unique range of machining tools and emphasises CeramTec's many years of experience and role as a supplier of machining processes. The SPK brand has always stood for the machining of cast iron materials. The further development of high-performance cutting materials under the umbrella of CeramTec now also enables the machining of HRSA materials as well as the machining of hard materials such as hardened steels or sintered metals.

S for Schneidplatten. (Schneidplatten is a German word and means cutting inserts. Due to SPK being a German company, the root for the abbreviation is to be found in the German language.) Under the SPK brand, CeramTec offers a unique range of indexable inserts made of ceramic cutting materials, polycrystalline cubic boron nitride (CBN) and whisker reinforced ceramics for the machining processes turning, hard turning, grooving, milling and boring. The portfolio is supplemented by respective tools and tool systems. Our high quality products and reliable services have long been associated with the SPK brand.

P for Process Supplier. With SPK, we provide our customers with maximum added value. That is why we deliver not only excellent cutting tools, but also expertise - understanding the machining process and how to optimize it. Our SPK engineering services enable customers to create highly productive and safe machining processes, which result in high-quality machining results – and the crucial advances in productivity.

K for Know-how. SPK – we know how it works. When it comes to the machining of cast iron, hardened steels and HRSA materials. As a company, we are looking back on a long-standing application and development experience: Ever since foundation of the Südplastik Gummi- und Kunststoff-Verarbeitung GmbH (SPK) in the early fifties, the company has been considered a pioneer for machining innovations and productivity. SPK has thus become an innovative traditional brand.

The new SPK brand symbolises CeramTec's strength in machining. The design of the brand has been modernised and adapted to today's requirements. This is because it stands for the next generation of innovative machining solutions with maximum productivity based on its tradition. However, the result is a new brand design that focuses on the fields of application of the machining solutions and is derived from the colour scheme for material classes of DIN-ISO 513.

What will change with the Launch?

SPK by CeramTec is an umbrella brand for CeramTec's product and service portfolio in the field of machining. SPK by CeramTec remains an integral part of CeramTec GmbH and will in future stand for the machining activities of CeramTec GmbH, i.e. all business data will remain unchanged.

We are introducing the new brand as a soft launch - it will gradually become more and more prominent.

The SPK by CeramTec Product Portfolio

Today, the high-performance cutting materials from SPK by CeramTec enable the reliable high-performance machining of cast iron materials, heat-resistant superalloys and the machining of hard materials. Whether turning, grooving, milling or boring, whether with standard or special tools - the machining solutions that we create as SPK Cutting Tools focus on specific cost and productivity benefits combined with process reliability.

Further detailed information on these topics can be found here:

SPK’s Big Five

Do you know SPK's BIG FIVE? SPK's BIG FIVE are the all-round package for your machining!

- SPK's BIG 1: Cutting materials for machining cast iron, HRSA and hard materials

- SPK's BIG 2: Special and standard geometries on cutting inserts

- SPK's BIG 3: Special tools and standard tools

- SPK's BIG 4: Engineering support with tool plans, time studies, development of special tools

- SPK's BIG 5: We provide on-site support, from the first chip to optimisation and troubleshooting. Worldwide.