Wire Drawing Tools with Optimized Ceramic Surfaces

The advantages of ceramic wire drawing tools include improved wire surface, consistent wire thickness, prevention of wire damage and breakage and significantly decreased machine setup times.

It would be very difficult to estimate how many kilometers of power lines traverse the Federal Republic of Germany alone. The spectrum of cable and wire products ranges from high voltage lines to telephone lines to the ultra-fine wires in electrical appliances that supply everything from circuits and components all the way to chips with electrical power. These wires consist almost exclusively of copper and its alloys – non-ferrous metals that combine minimal electrical impedance with low manufacturing costs.

The more or less fine wire variants all start out as raw wire. In the foundry, a bar is cast from the liquid metal in a continuous process; the bar is then rolled into a blank. The resulting cast wire rod has a diameter of 8 mm. To create a copper wire that is often only a fraction of a millimeter thick from the cast wire rod, wire drawing machines pull the soft material over what are known as drawing tools until the desired end thickness of the wire is achieved. In this process, the wire is guided like the rope of a hoist through the many rollers or cones, thereby transferring the extreme tensile force required for forming onto the wire.

The drawing cones and rollers used here are subject to extremely high levels of stress and wear depending on the material used.

CeramTec advanced ceramic materials can successfully handle these rough conditions and high mechanical demands while maintaining an economical tool service life: Guides and guide rolls, rollers or drawing cones made of alumina, zirconium oxide or silicon nitride can fully leverage their strengths as forming tools for non-ferrous metal wires.

Wire Drawing Tools with Optimized Ceramic Surfaces

- Exact particle size definition in the ceramic surface material

- Cobblestone pattern significantly increases contact area thanks to a finely polished surface

- Constant torque levels yield consistent wire thicknesses

- Prevention of damages to coated wires

- Prevention of wire breakage

- Low maintenance costs

- Extended maintenance intervals

- Extended machine service life

- Dramatic improvement in wire quality

High Wire Quality and Process Reliability Thanks to Ceramic Optimization and a Finely Polished Surface

Machines and wires are subject to extremely powerful forces whenever wire is drawn under full tension on the rollers and drawing cones of a wire drawing machine. The surfaces of the tools used must be perfectly adapted to the wire’s requirements in order to ensure that the surface of the wire does not suffer any permanent damage. The tribological requirements for wire drawing tools demand surfaces with a high contact area and optimum surface roughness.

Over the past few years CeramTec has continued to develop and optimize the ceramic surfaces of the drawing tools it manufactures. This has enabled CeramTec to precisely define the particle size of the ceramic materials used, because this is a decisive factor in the surface quality and roughness that can be achieved in the drawing tools.

The surfaces of CeramTec drawing tools are polished with diamond tools to eliminate smaller surface irregularities that stem from the antecedent grinding process. This gives the ceramic tool surfaces what is known as a “cobblestone pattern” at the end of the process. This special pattern significantly increases the contact area on the roller or drawing cone. A high contact area on the surface of the tool provides the machine with constant torque at later stages of the wire drawing process along with a precisely adjustable slip factor. The surfaces of CeramTec ceramic drawing tools also ensure that any lubricants used in the forming process adhere consistently.

In addition, the smooth polished surface of a CeramTec drawing tool does not adversely affect the surface of coated wires as much as purely ground surfaces, whose microscopic elevations act like tiny knives that damage the coating in the forming process and can lead to corrosion between the carrier material and the coating.

Using ceramic tools in wire drawing noticeably improves the surface of the wire, because it prevents possible corrosion damage to coated wires and ensures consistent wire thickness. This also reduces the chance of wire breakage. The result is a significant decline in maintenance costs, a vastly extended service life and a considerable reduction in total setup times. All of these factors lead to noticeably longer machine running times and markedly improved product quality.

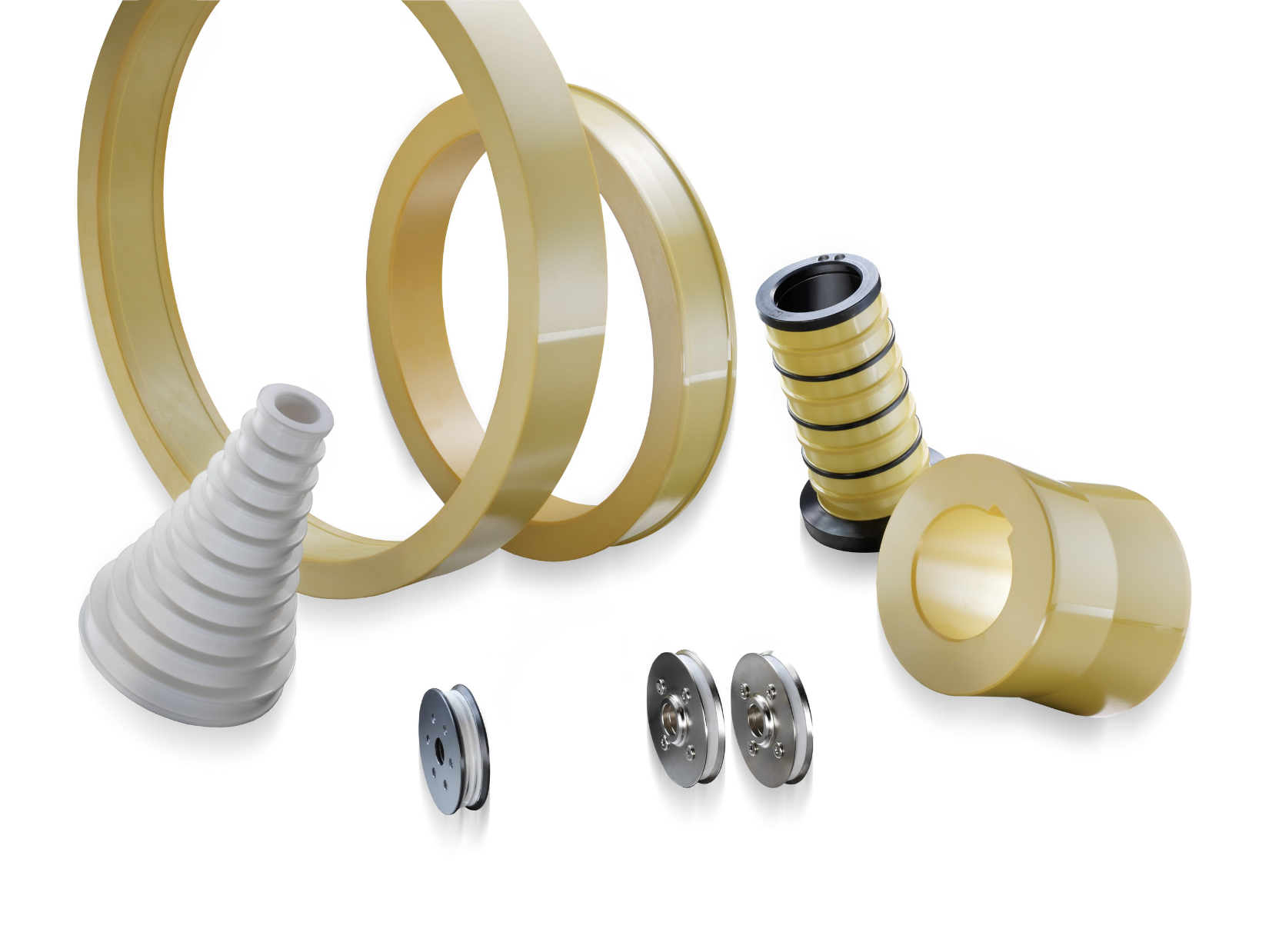

The CeramTec ceramic drawing tool product range encompasses ready-to-install and balanced metal/ceramic composites as rollers or drawing cones in various stages as well as solid ceramic components and carbide-coated drawing tools.

CeramTec’s Plochingen site also has a test center at its disposal for simulating wire drawing processes in real operating conditions, making it possible to solve customer-specific problems in the field of wire drawing. Our wire drawing experts at the Plochingen site are happy to help you with any specific inquiries you may have.

“CeramTec ceramic tools are the standard for wire drawing of non-ferrous metals for all leading manufacturers worldwide.”

CeramTec can cost-effectively manufacture solid ceramic forming rings and large components with a diameter of up to 485 mm. This enables CeramTec to meet requirements that have grown tremendously in recent years.

A prominent example of this is the 483 mm drawing ring for Syncro F 13 wire drawing machines. Please contact the wire drawing experts directly at our Plochingen site if you are interested in learning more.

“Solid ceramic large rings up to half a meter in diameter are dependable replacements for their steel predecessors.”

Auxiliary tools for wire manufacturing including guide rolls and guide elements made from zirconium oxide and silicon nitride; ceramic inlet nozzles and guide nozzles, adjustable guides, eyelets and various guide plates are also characterized by their outstanding service life and superior resistance to temperature fluctuations. CeramTec guide rolls with polished bearing seats eliminate the need to install ball bearings.

For more information, please contact the CeramTec wire drawing experts at our site in Plochingen.

“Their chemical and thermal resistance make these materials suitable for use in molten metals, acids and lyes.”