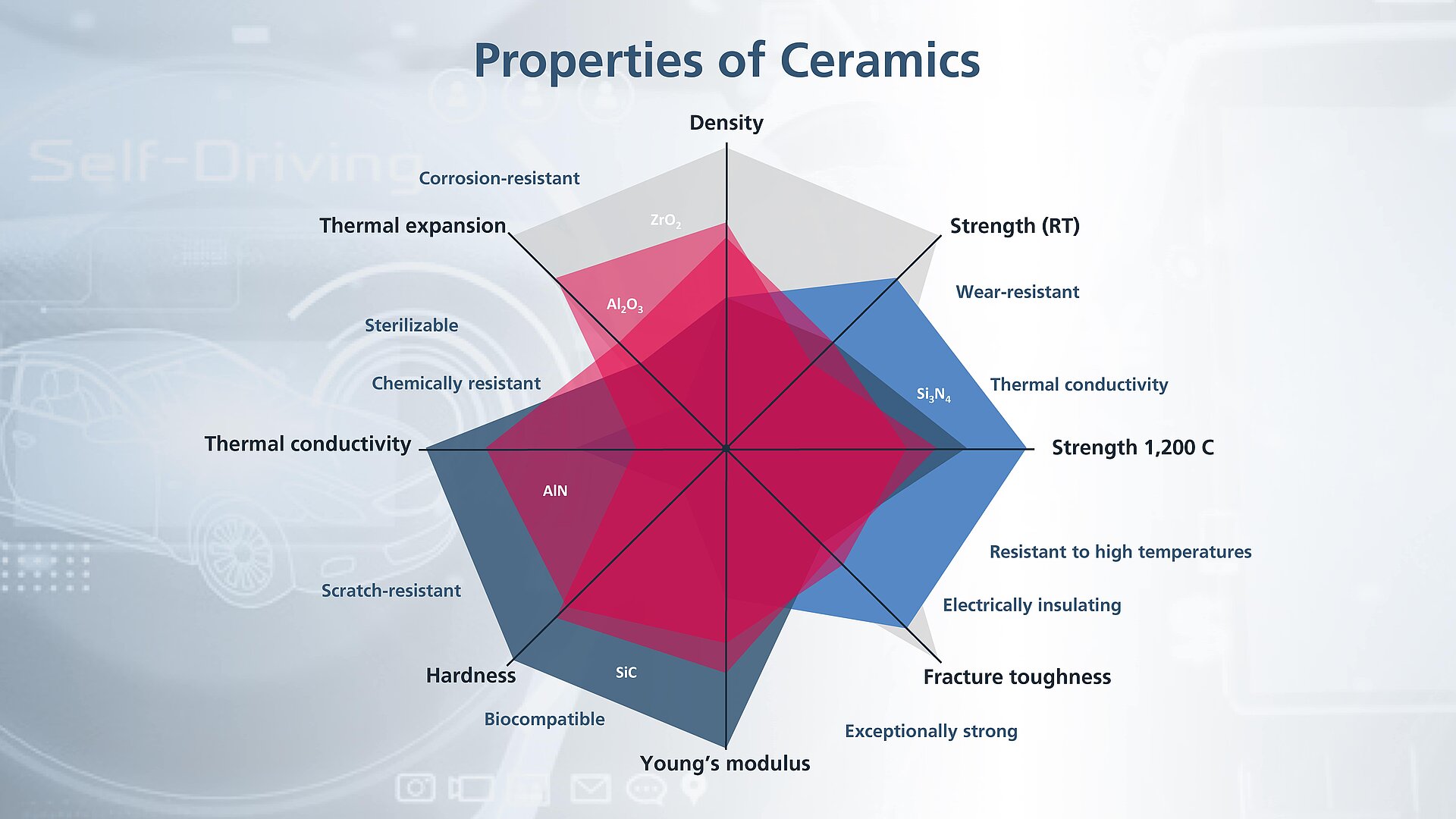

Silicon Nitride (Si3N4)

Silicon nitrides (Si3N4) feature an excellent combination of material properties. They are nearly as light as silicon carbide (SiC), but their microstructure gives them excellent thermal shock resistance and their high fracture toughness makes them resistant to impacts and shocks.

The microstructure consists of elongated crystals that interlock into micro-rods. One application where this combination of properties has proven particularly useful is the machining of gray cast iron or cast iron with ceramic inserts. Unlike hard metals or other cutting materials, machining processes can be performed with ceramic inserts at maximum speed without the use of cooling lubricants.

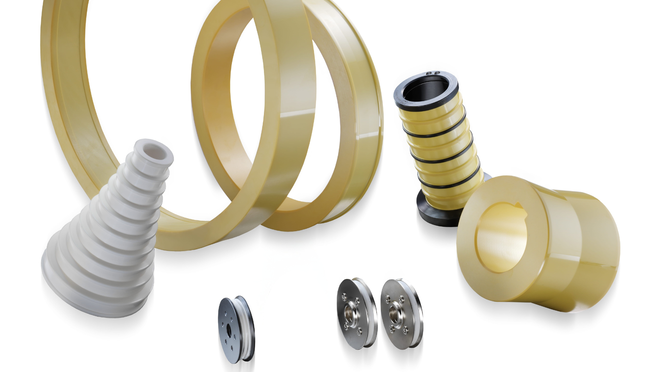

Application Examples

The combination of good tribological properties and excellent fracture toughness makes silicon nitride ceramics predestined for applications as balls and rolling elements for light and extremely precise bearings, heavy-duty ceramic forming tools and automotive components subject to high stress. And the good thermal shock resistance and high temperature resistance is exploited in welding processes. In the future, silicon nitride could play an important role in energy-efficient machines and high-performance electronics, as it is extremely resilient yet lightweight.

Discover all products & solutions made of silicon nitride ceramic in the drop-down menu.

Properties of Silicon Nitride (Si3N4)

- Very low density (3.21 g/cm3)

- Very high fracture toughness (7 MPam1/2)

- Good flexural strength (850 MPa)

- Very good thermal shock resistance: High thermal stress parameters (569 K)

- Maximum operating temperature in an oxidizing atmosphere: 1,300°C

- Maximum operating temperature in a neutral atmosphere: 1,600°C