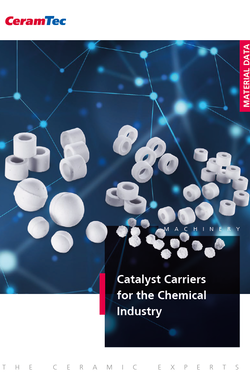

Catalyst Carriers for the Chemical Industry

Have you ever wondered how industrial processes such as plastics production or exhaust gas purification can be made more efficient and environmentally friendly? As experts in technical ceramics, we offer customised catalyst carriers that answer precisely these questions. Our ceramic carrier materials - from rings and spheres to granulates - are characterised by high mechanical strength, thermal stability and chemical resistance. They therefore make a decisive contribution to controlling reactions in a targeted manner and increasing efficiency in the chemical industry.

Ceramic catalyst supports are an important component of heterogeneous catalysis. They are primarily used in highly selective oxidation processes. In heterogeneous catalysis in the chemical industry, bulk catalysts are used to convert gaseous or liquid reactants. The actual catalyst, the catalytic substance, can be used as a mould alone or with a carrier. Carrier materials are necessary if high demands are placed on the mechanical strength of the catalyst, if the catalytically active substance must be present in a thin layer or if the aim is to save valuable catalyst substances.

Have we piqued your interest? Then let us work together to develop the specific moulds you need - from catalyst carriers in laboratory quantities to large-scale production.

Materials for ceramic catalyst carriers

A wide variety of materials offered by CeramTec can be used for catalyst carriers.

Dense catalyst carriers (for shell type catalysts)

Porous catalyst carriers (for impregnated catalysts)

The porosity can be adjusted to the respective customer needs for the required surface, e.g. it can range from simple porosity to a special bi-modal and tri-modal pore distribution.