Silicate Ceramics

Early developments in the field of technical ceramics began with the use of silicate ceramics for electrical insulation. Silicate ceramics are manufactured for the most part from natural raw materials. Silicate ceramics such as mullite, cordierite, steatite or aluminium silicate - used creatively and intelligently - open up impressive cost-cutting potential and are used in numerous applications in electronics, energy and environmental technology where reliable insulation and thermal resistance are required.

Very different types of multiphase ceramics can be produced with different properties by varying the type and quantity of raw materials. Silicate ceramic materials include:

- Porcelains: Alkali – aluminum silicates (Typ C140)

- Steatites: Magnesium silicates (Type C221, 230)

- Cordierites: Alkaline earth – silizium silicates (Type C410, C520, C530)

- Mullites: Alumina-silicon oxide compositions (Type C610, C620/C780)

To ensure that the enhanced properties of ceramic materials are fully exploited, CeramTec's silicate technology designers don't just think in terms of products - they think in terms of system solutions. Their expertise in the manufacture and integration of silicate ceramic components helps them to develop creative, ceramic-oriented solutions for every application.

Highly efficient manufacturing technologies enable the production of difficult-to-design products with maximum precision, even in high volumes. CeramTec also performs finishing and assembly work on complex components and supplies ready-to-install silicate ceramic components for cost-saving system solutions.

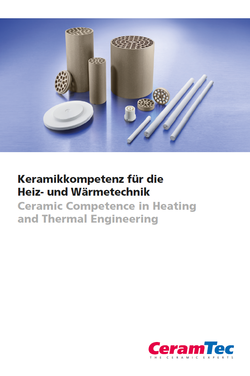

Products & Solutions with Silicate Ceramics

Silicate ceramic components are used in electronics and electrical engineering and act as electrical insulation in fuses, circuit breakers, thermostats and in lighting technology. The ability of silicate ceramic materials to provide thermal insulation is also utilized in heating, environmental and thermal engineering applications.

Porous components are produced for the emission of fragrances and insecticides, as carriers for catalysts or for various applications in laboratories. Precision components for applications in measurement technology and products for laboratory use and mixed media complete CeramTec’s range of silicate ceramic products.

Last but not least, grinding balls and feed stones made of steatite are very suitable for applications where a high grinding effect but low abrasion of the grinding medium is required.

Discover all products & solutions made of silicate ceramics in the drop-down menu.