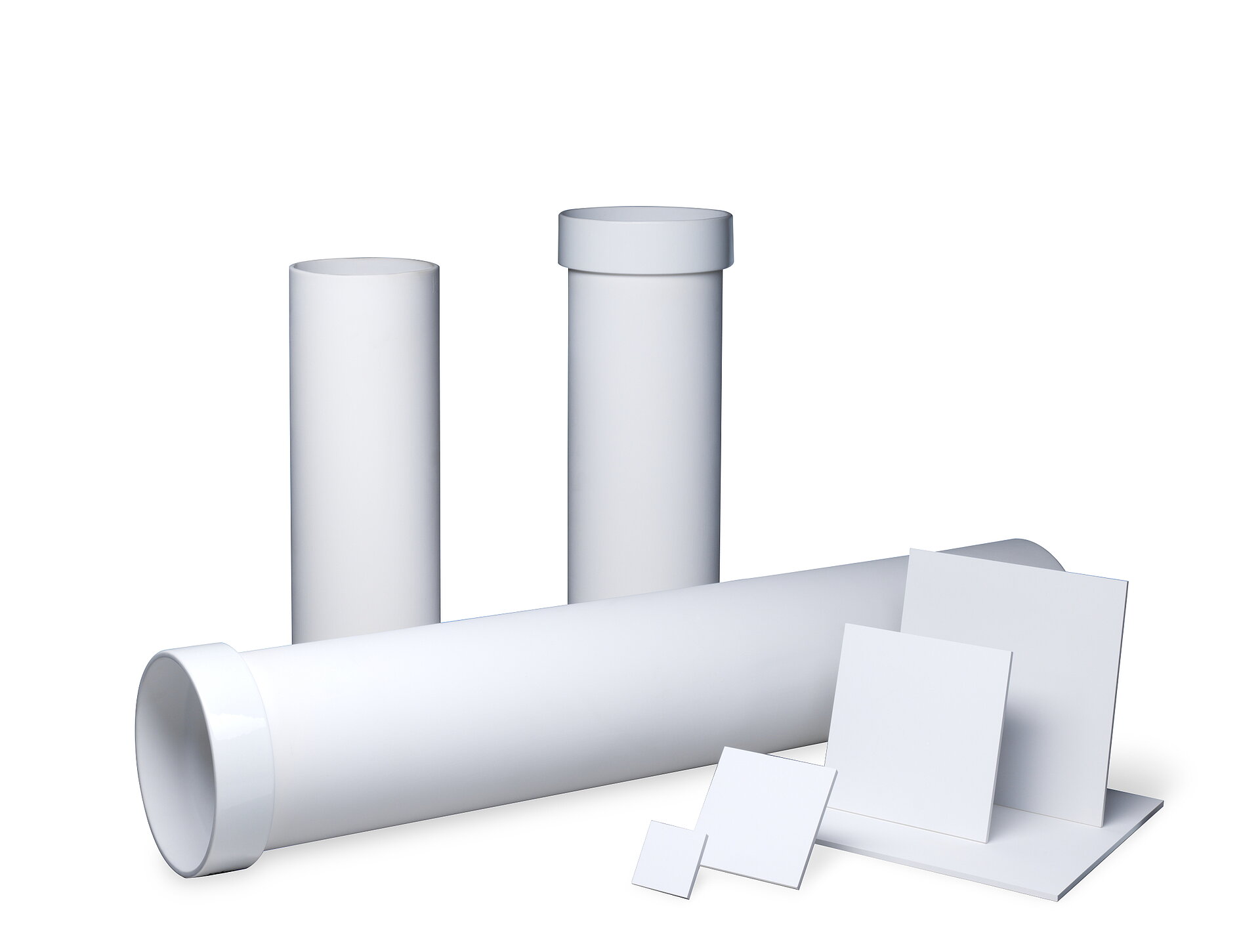

High Alumina Porous Products

At CeramTec, we develop high-performance ceramics with precisely defined porosities and pore sizes - customised for demanding technical applications. Have you ever wondered how aggressive acids can be safely controlled or how soil moisture measurements can be made more precise at an agricultural level? Our aluminium oxide-rich, porous products combine chemical resistance, mechanical robustness and high temperature tolerance. They are therefore ideal for electrolysis, filtration, agriculture or electrochemical processes.

Electroplating

High purity alumina ceramic pots also known as P80 oxamat or diaphragma cells have established themselves as standard material for chrome plating process. Due to its excellent chemical resistance it can withstand even aggressive chromicsulfuric acid. As sulfuric acid is used in electroplating, plant operators need a resistant ceramic that must allow chromium ions to pass through. Metallic impurities can be prevented with the aid of such a permeable medium.

Electrochemical industry

As of high mechanical and chemical resistance, diaphragma plates are also used in electro chemical process where electrical energy is converted to produce the chemicals. These discs allow only certain ions to pass from anode to cathode. The effect is reverse of a battery, where chemicals are converted into electrical energy.

Filtration

Cross-flow filtration is a filtration process in which a suspension is pumped through porous tubes, so-called membranes, and the filtered liquid, the permeate, is drawn off transversely to the direction of flow. Ceramic membrane carriers score points with their high mechanical, chemical and thermal resistance, among other things.