Platforms, Designs & Variants

Suitable for almost any cooling capacity: Discover platforms, designs, properties and technical specifications of ceramic heat sinks for air and liquid cooling.

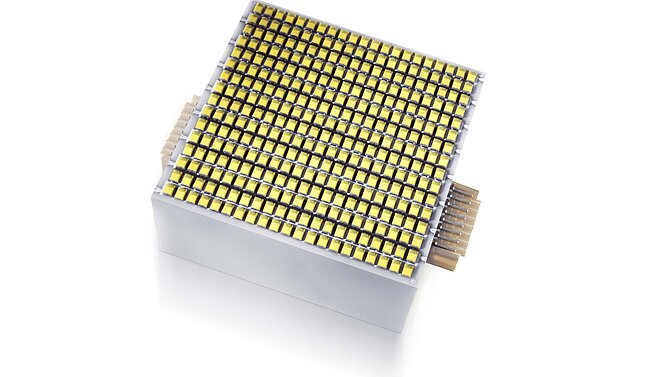

Ceramic heat sinks provide efficient heat dissipation for electronic components in air and liquid cooling systems. Thanks to their high thermal conductivity, they enable rapid and even distribution of the heat generated, resulting in improved cooling performance.

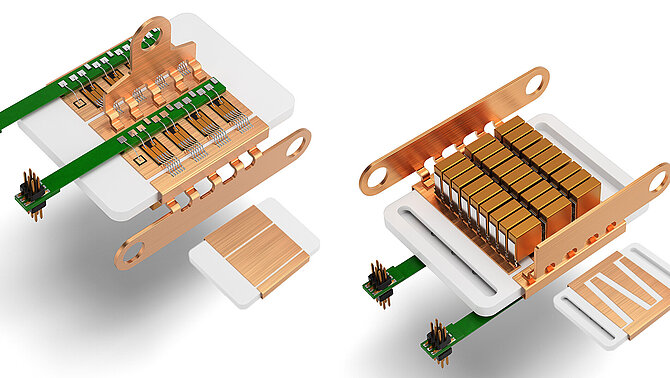

Ceramic Coolers

- Integrated cooler

- Connecting element

- Power chips next to the driver electronics

- High thermal connectivity and high insulation voltage

- High current carrying capacity

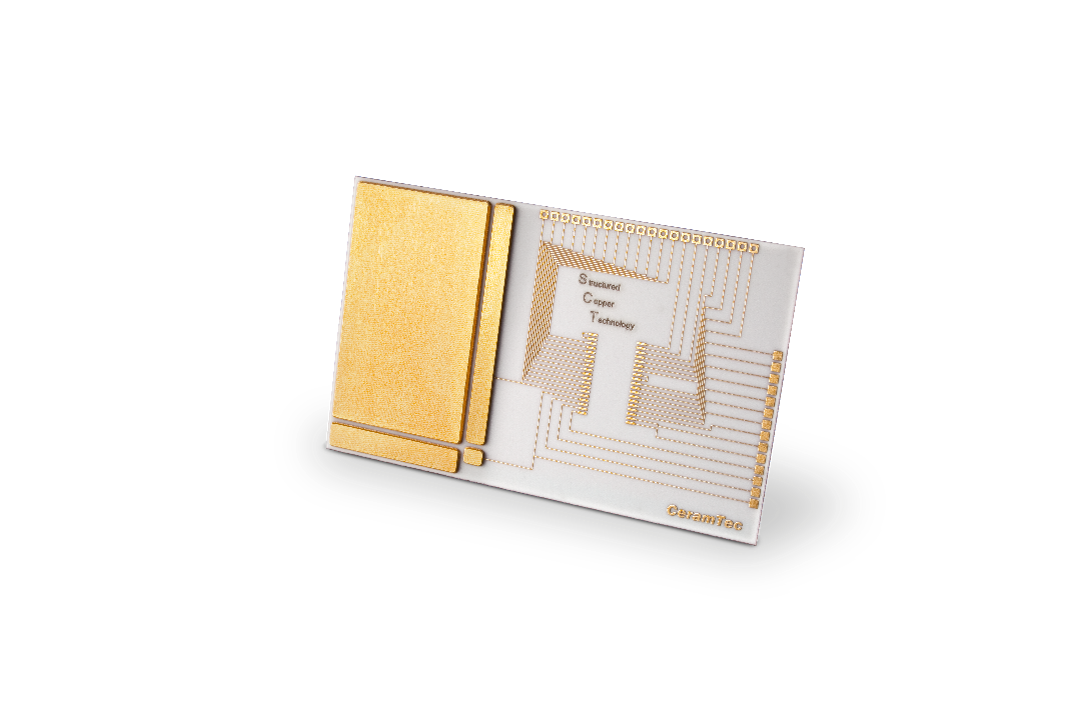

- Double-sided metallisation and component mounting

- High operating temperature for new chip generation

- Free choice of coolant

- High integration

- Small volume

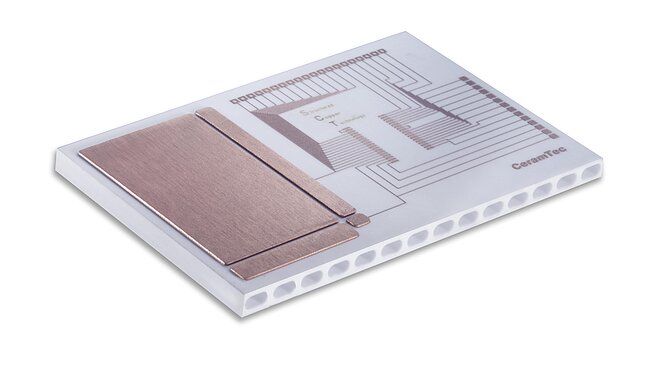

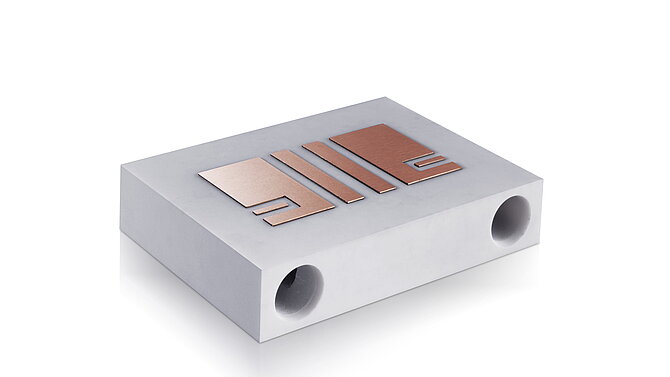

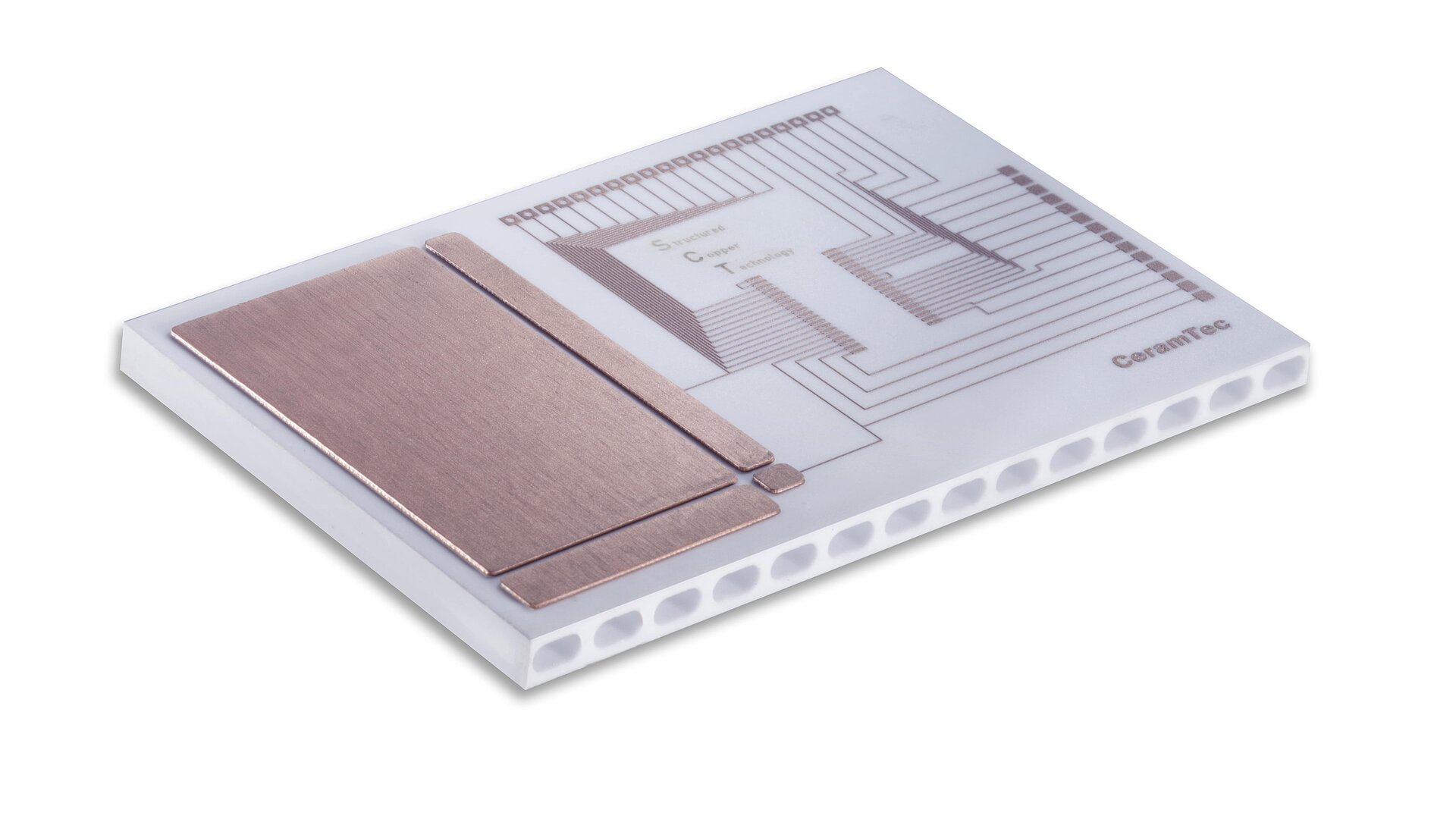

Shapes and Variants of our Ceramic Heat Sinks

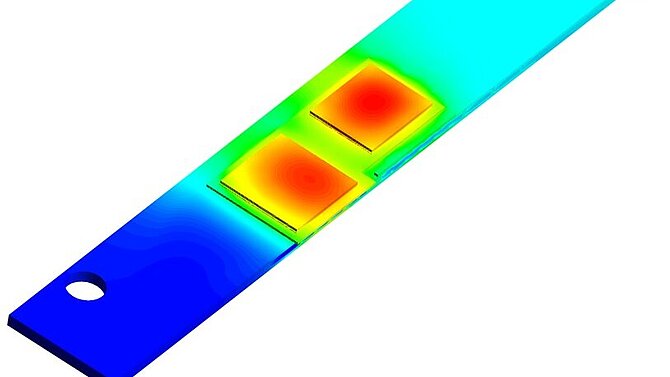

The dimensions, shape and design of the CeramCool® heat sinks, the number of fins or cooling channels, depend on the specific requirements of the intended application. At high power densities, air cooling reaches its limits and liquid cooling becomes necessary.

Even simple linear pipe systems provide amazing cooling performance. However, complex internal contours for particularly homogeneous or targeted cooling are also possible. In addition to CeramCool® standard variants for air and liquid cooling, customised designs can also be realised. It is also possible to simulate and analyse thermal parameters during development prior to the production of prototypes or small series.