Silicon Carbide (SiC/SiSiC/SSiC)

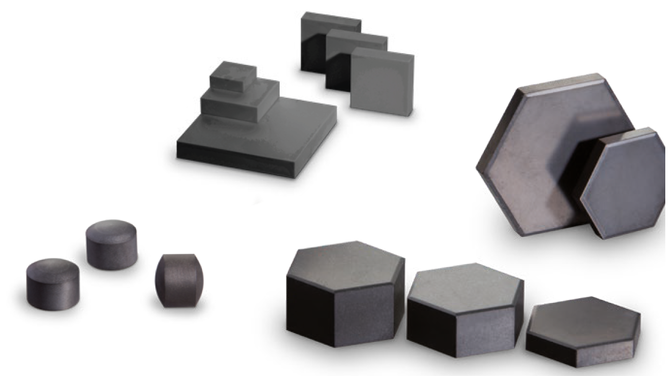

Silicon carbide behaves almost like a diamond. It is not only the lightest, but also the hardest ceramic material and has excellent thermal conductivity, low thermal expansion and is very resistant to acids and lyes. The variants SSiC (sintered silicon carbide) and SiSiC (silicon infiltrated silicon carbide) have established themselves. The latter is particularly suitable for the production of complex large-volume components. ROCAR® silicon carbide is used in numerous applications.

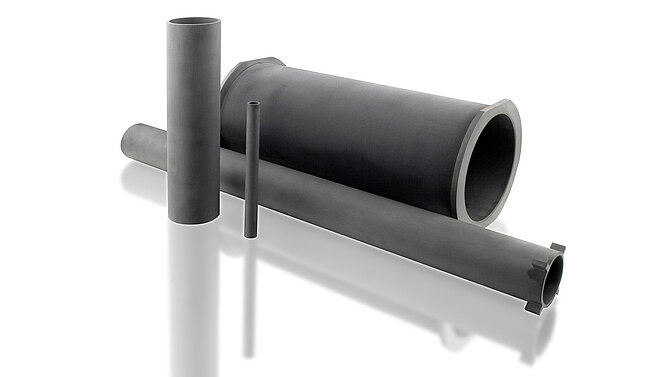

With silicon carbide ceramics the material properties remain constant up to temperatures above 1,400°C. The high Young’s modulus > 400 GPa ensures excellent dimensional stability. These material properties make silicon carbide predestined for use as a construction material. Silicon carbide masters corrosion, abrasion and erosion as skillfully as it stands up to frictional wear. Components are used in chemical plants, mills, expanders and extruders or as nozzles, for example.

ROCAR® Silicon Carbide

In industrial plants in general, as well as in large chemical plants, plants in the food industry or in the field of turbine and heating technology, material consumption is very high - and so are the material costs.However, metal components quickly reach their limits in aggressive operating environments, as a wide range of stresses such as high thermal loads, friction, wear and corrosion, alone, in combination or even in interaction with each other, take their toll.

Mastering challenging operating conditions

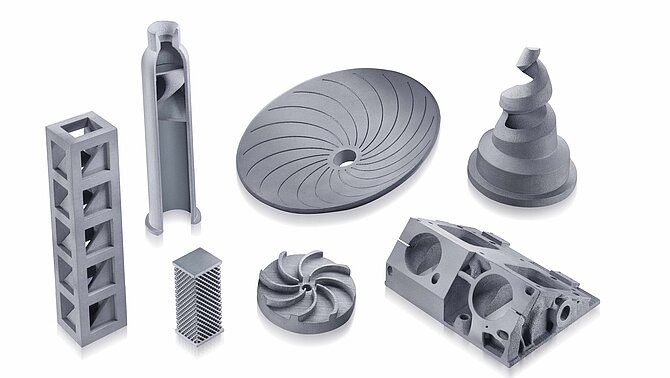

This is where ROCAR® silicon carbide ceramics from CeramTec come into play: for pipes, bushings & bearings, nozzles, plain bearings, seal rings, valves, semiconductor components or special components in a wide variety of designs made from this ceramic material, demanding and aggressive operating conditions are no challenge and, compared to metals, it provides very economical solutions with longer service lives.

Components made of ROCAR® silicon carbide are also used in 3D printing and ballistics as well as in chemical plants, shredders, expanders and extrusion machines. In addition, ROCAR® silicon carbide is toxicologically safe and therefore ideally suited for use in the food industry.