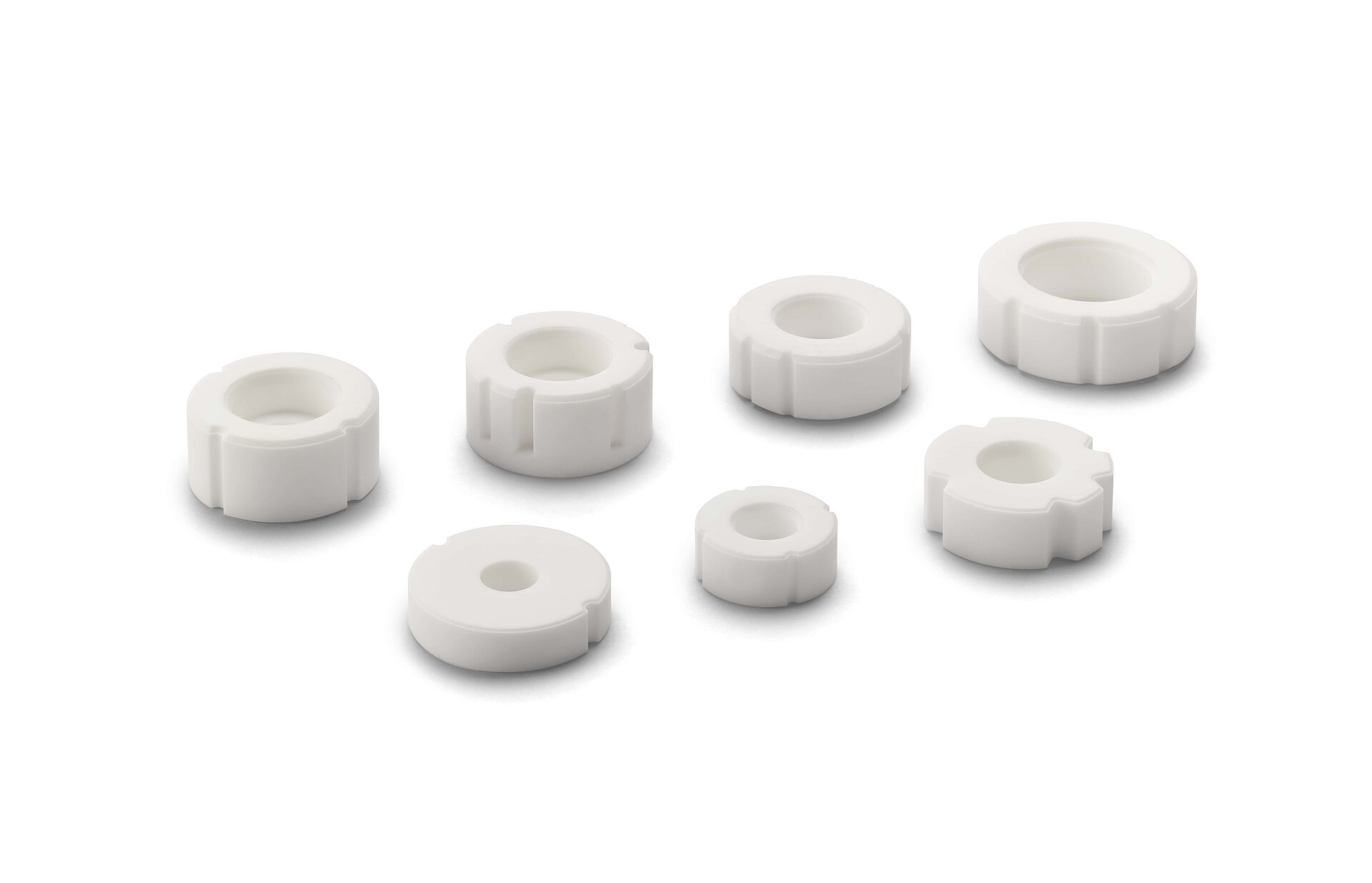

Ceramic Diaphragms for Pressure Sensors

Whether in medical equipment, air conditioning, food & beverage or chemical industry – consistent and reliable pressure measurement utilizing state-of-the-art pressure sensor technology is cruicial for a wide range of industrial apllications. Depending on the sensor technology, different ceramic elements made of aluminium oxide are used and contribute to the perfect interaction between sensor and transformation element and thus to the accuracy of the measurement results.

Different measurement applications require varied ceramic components. In capacitive measurement a ceramic carrier and a ceramic diaphragm, deformable by pressure, form the two capacitor plates. Under pressure, the distance between the two plates gets smaller, the capacitance changes as the load deforms the diaphragm.

Ceramic based resistive pressure sensors use metallic strain gauges, applied by thick film screening printing on the reverse side of the diaphragm. The applied pressure increases the resistance as the pressure deforms the material. The resistance change os measured vie a Wheatstone bridge circuit.

- Better corrosion resistance

- Distinct lower production costs compared with piezoresistive sensors (no oil as transmitting media necessary, no hermetting sealing)

- Good thermal stability (compared with piezoresistive sensors)

- Range of use : 2 – 600 bar

Image: Pressure Sensor, Metallux SA, www.metallux.ch