Aluminium Nitride AlN Substrates

Achieving maximum performance in minimum space inevitably means that power semiconductors develop ever higher temperatures. To protect the components and connection technology, this heat must be dissipated quickly and reliably. This is where CeramTec's aluminium nitride ceramic Alunit® sets standards.

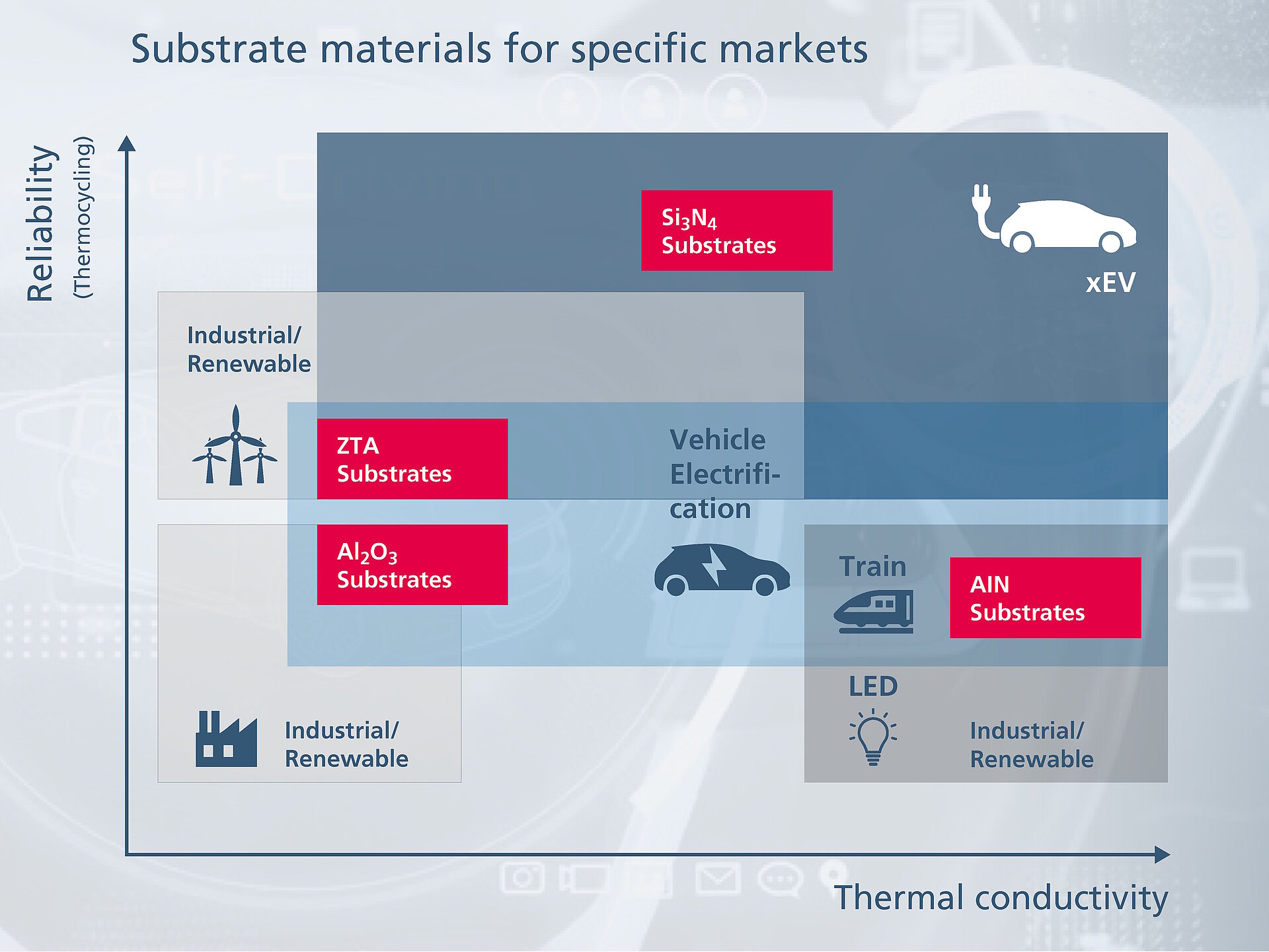

Substrates made of aluminium nitride AlN HP convince with outstanding thermal and electrical properties, high bending strength (450 MPa), longer durability (thermocycling), excellent thermal conductivity (170 W/mK) as well as high resistance to abrasion and and oxidation. AlN HP is therefore ideal for very high power electronics and is used in the areas of trains & railways, industry and renewable energies as well as in high power density modules.

Due to the coefficient of expansion adapted to chip materials, AlN HP is excellently suited as an insulation material in the field of power modules. Aluminium nitride substrates also have a significantly higher thermal conductivity with better temperature resistance and insulation capability than PCB materials. This makes such materials suitable for use in high-power LEDs and passive components such as chip resistors.

Aluminum Nitride (AlN) - Discover more information & examples of use

Technical Values & Parameters

Physical properties

- Density: ≥ 3.34 g/cm3

Surface properties

- Ra value: ≤ 0.4 µm

Mechanical properties

- Bending strength DR sigma 0 (3 Point Method): ≥ 450 MPa

- Fracture toughness (IF method): ≥ 3.0 MPa*√m

- Young´s modulus: ≥ 300 GPa

Thermal properties

- CTE: 100-800°C: ± 4.8 - 6.2 10-6/K

- Specific heat capacity at 25°C: 0.72 J/gK

- Thermal conductivity at 20°C: ≥ 170 W/mK (+/- 10% measurement tolerances)

Electrical properties

- Dielectric constant at 1 MHz: +/- 8.5

- Dielectric loss factor at 1 MHz: ≤ 1 (10-3)

- Volume resistivity at 20 °C: ≥ 1014 Ω cm

- Dielectric strength: ≥ 15 kV/mm

Geometry - Masterplates

- Standard size: 7.5“ x 5.5“ (+/- 1,2%)

- Thickness: 0.38 to 1.5 (+/- 10%)

- Warpage/camber: 0.2 - 0.6%

Geometry - lasered substrates

- Thickness: 0.635mm (0.025")

- Length and width tolerance: + 0.20 mm / - 0.05 mm (+0.0079" / 0.002")