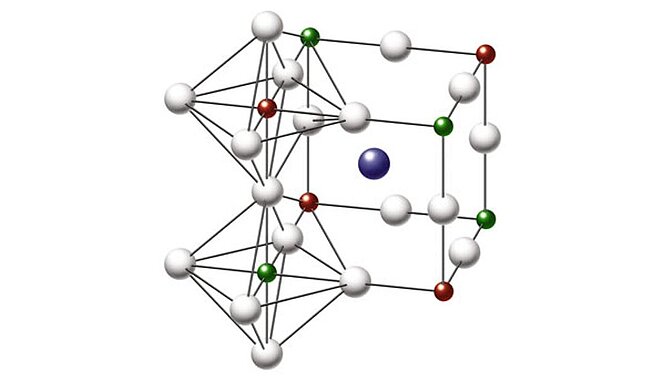

Piezoceramics

CeramTec has developed specialist high performance materials for implementation in piezo applications. Piezoceramic components are often exposed to high stresses and must still fulfil their functions with maximum reliability. With their different qualities and application options, SONOX® and PZT materials are synonymous with high performance and maximum reliability in the world of sensors and transducers.

Material Categories

Piezoceramic materials are categorized according to their chemical composition and, on the other hand, by the specific application conditions. Besides the typical parameters (see data sheets), selection criteria include behavior under high electrical and mechanical loads. The material categories are defined below:

Materials for power transducers

SONOX® P4, SONOX® P8, PZT401, PZT807

These materials withstand both high electrical driving voltages and intense mechanical (pressure) loads and are characterized by:

- Low dielectric loss

- Permittivity in between 900 and 1400

- High mechanical quality factor in between 500 and 2000

- High Curie temperature

- High coercive field strength

Materials of this type are specifically well suited for high-performance ultrasonic applications in the range from 20 kHz to several MHz.

Materials for sensor applications

SONOX® P5, SONOX® P502, SONOX® P504, SONOX® P508, PZT 503, PZT5A1, PZT 5A4, PZT5H1

- Permittivity in between 1000 and 2000

- High piezoelectric activity (d33 ≥ 400 * 10-12 C/N)

- Low mechanical quality factor (≤100)

Sensor applications are mainly combined systems in which the piezoceramic is used as ultrasonic transmitter on the one hand and as a receiver on the other hand. SONOX® P502 and SONOX® P504 are specially developed materials with a high rate of thermal and temporal stability. For this reason, they are very suitable for automotive applications and others in the area ranging from –40 to +160º Celsius.

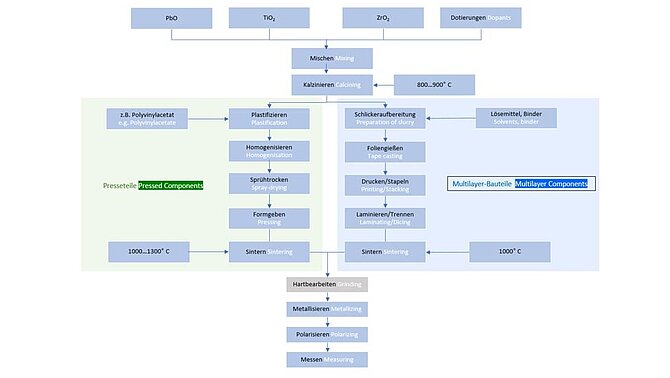

Lead-free piezoceramic materials

Several lead-free materials are available upon request.

Applications & Materials

| Typical Applications | Suitable Material |

Ultrasonic cleaning Sonar technique | SONOX® P4 PZT401 PZT5H1 |

Sensor technique Material testing Medical diagnostics and therapy | SONOX® P5 PZT5A1 PZT5A4 SONOX® P502 PZT503 SONOX® P504 SONOX® P508 |

| Ultrasonic machining and joining techniques (welding, drilling) | SONOX® P8 PZT807 |

Actuators Piezo electric generators | SONOX® P505 SONOX® P53 PZT5A4 |

Performance Data

| Power transducers | Sensor applications | Actuating applications | |

| Relative permittivity ε33 Τ/ε0 | 1,000 – 1,395 | 1,500-3,400 | 1,800 – 3,800 |

| Loss factor tan σ | 1.6x10-3 – 3.0x10-3 | 12x10-3 – 20x10-3 | 15x10-3 – 16x10-3 |

| Coupling factor kP | 0.54 – 0.58 | 0.59 – 0.62 | 0.65 |

Charge constant d33 10-12 C/N | 240 – 315 | 390 – 620 | 475 – 680 |

| Voltage constant g33 10-3 Vm/N | 500 – 1,200 | 22.7 – 33.1 | 20.2 –28.5 |

| Quality Qm | 500 – 1,200 | 60 – 90 | 75 – 80 |

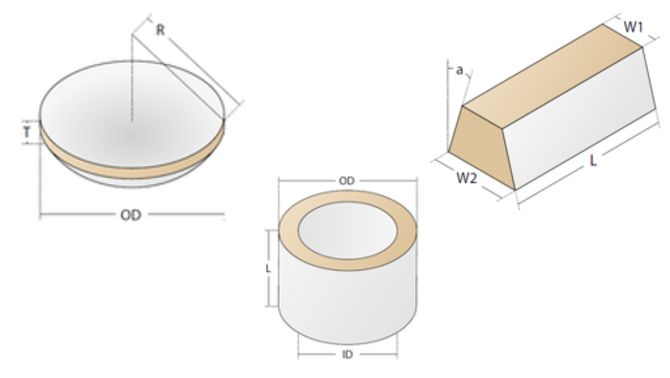

We are your Partner for Piezoceramic Solutions

Given this broad diversity of applications, it is recommended to discuss with CeramTec´s experts at the development stage of a new product or system. In dialogue with your company‘s experts, CeramTec can help to specify application conditions, requirement criteria and design prerequisites, and to propose costeffective solutions.

Advanced manufacturing methods enable CeramTec to produce piezoceramic components of unsurpassed quality in large volume. Our companywide quality management system assures that its products and services will be fully in line with customer‘s expectations.

RoHS Directive

RoHS: Directive on the Restriction of the use of certain Hazardous Substances in electrical and electronic equipment.

This directive describes the avoidance of hazardous or harmful substances in electrical or electronic equipment. CeramTec's Multifunctional Ceramics Division sells ceramic components and is therefore not directly affected by this directive - but our customers may be. The main component of piezoceramic components are lead compounds such as lead zirconate and lead titanate. Unfortunately, this is unavoidable. This is also the view of the European Commission. This is why, for example, lead compounds in ceramic compounds are exempt from the ban in the "End-of-Life Vehicle Regulation".

Despite this, or precisely because of this, we want to support our customers in this respect: CeramTec offers to take back piezoceramic components and to dispose of them in an environmentally friendly way or to recycle them. The prerequisite is that the piezoceramics are delivered without foreign components (i.e. not in the housing or cast in). If you are interested in recycling, please contact us. We will be happy to make you an offer.

Another step towards RoHS conformity is the development of the lead-free piezoceramic special material SONOX® P1 LF by CeramTec.