Metal Matrix Composite (MMC)

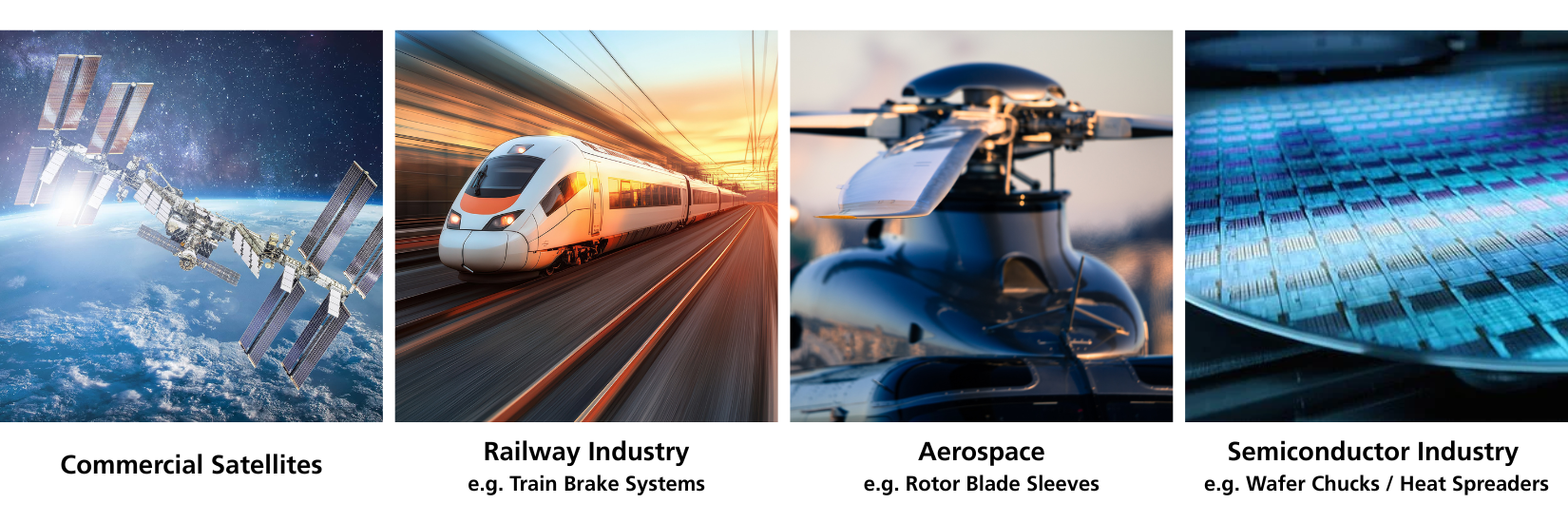

The range of applications for highly stressed light metal components, primarily made of aluminium, but also magnesium or titanium, is constantly expanding. The motivation for using light metals in automotive engineering is to reduce weight and thus lower fuel consumption and pollutant emissions. With a view to e-mobility, the weight reduction also enables a longer range, while the materials simultaneously withstand higher mechanical stresses and thus contribute to longevity.

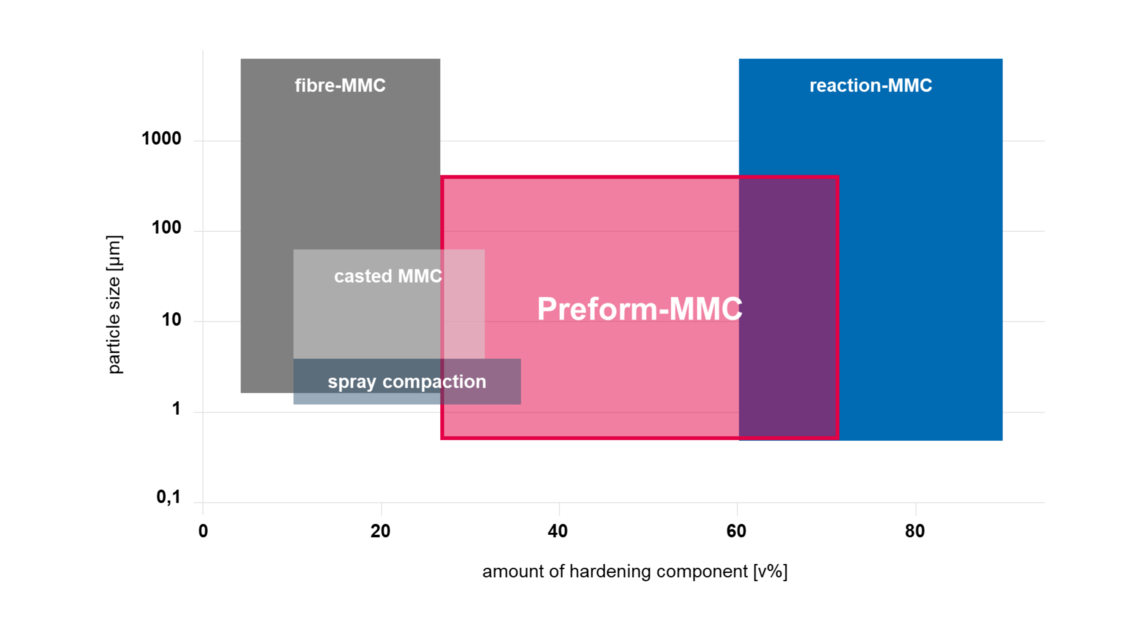

Light metal constructions reach their limits where high tribological, mechanical or thermal loads occur. The solution lies in the targeted reinforcement of lightweight components at the points of maximum stress. Such composite materials made of metal and ceramic, known as metal-matrix composites (MMC), consist of a metal (matrix) reinforced with hard ceramic particles.

Metal-matrix composites combine the advantages of both material worlds: namely the low weight and good formability (ductility/plasticity) of metal on the one hand and the high performance and wear resistance of ceramic on the other.

CeramTec supplies the decisive basis for this - the high-precision ceramic preforms that are introduced into the die-casting process, where they create the locally reinforced MMC structures.

The latest innovations lead to a significant reduction in the production and processing costs associated with MMCs. As the world's leading supplier of technical ceramics, CeramTec has developed a process with which lightweight MMC components can be produced efficiently and economically in large series while maintaining the highest quality standards.

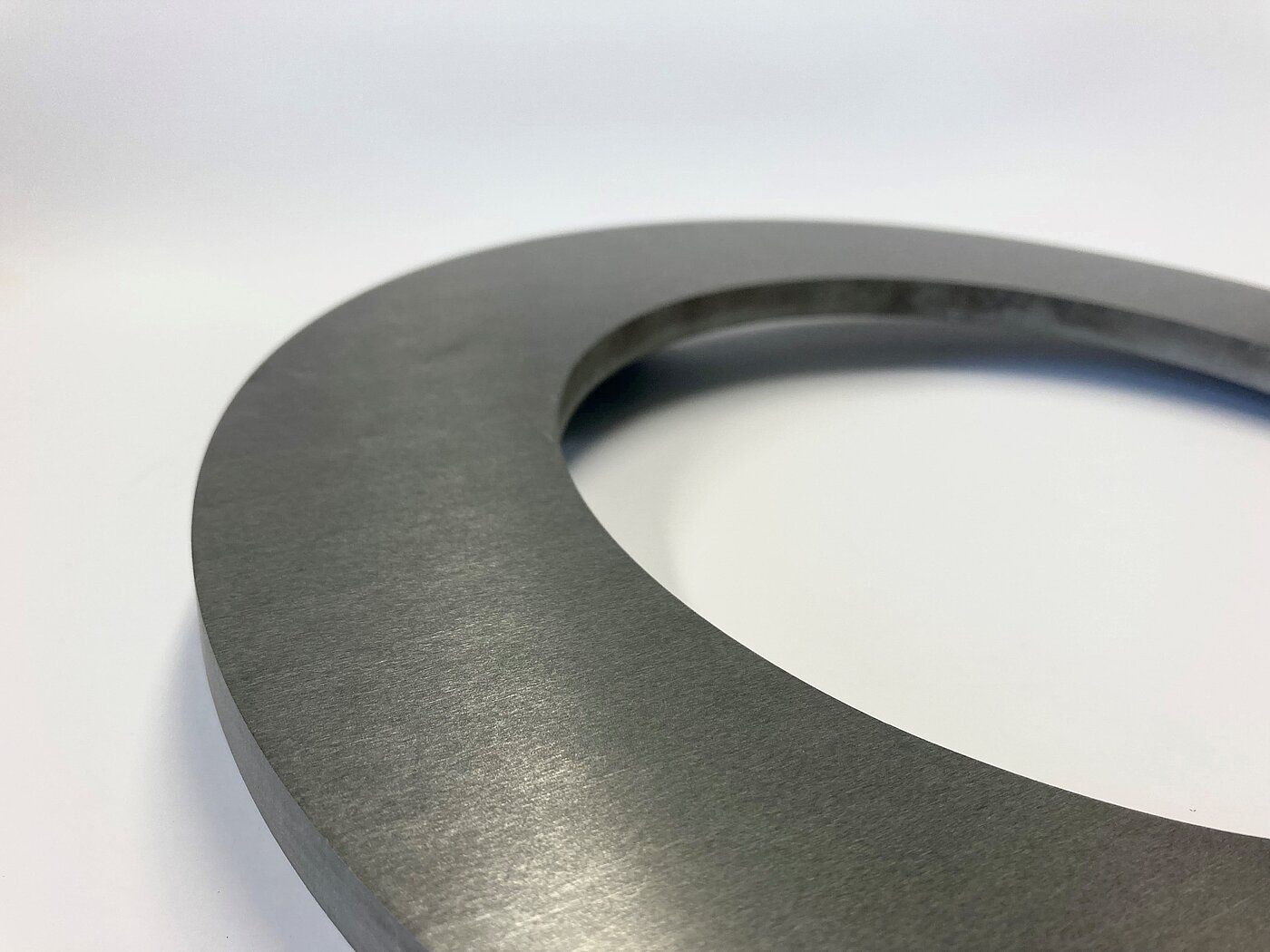

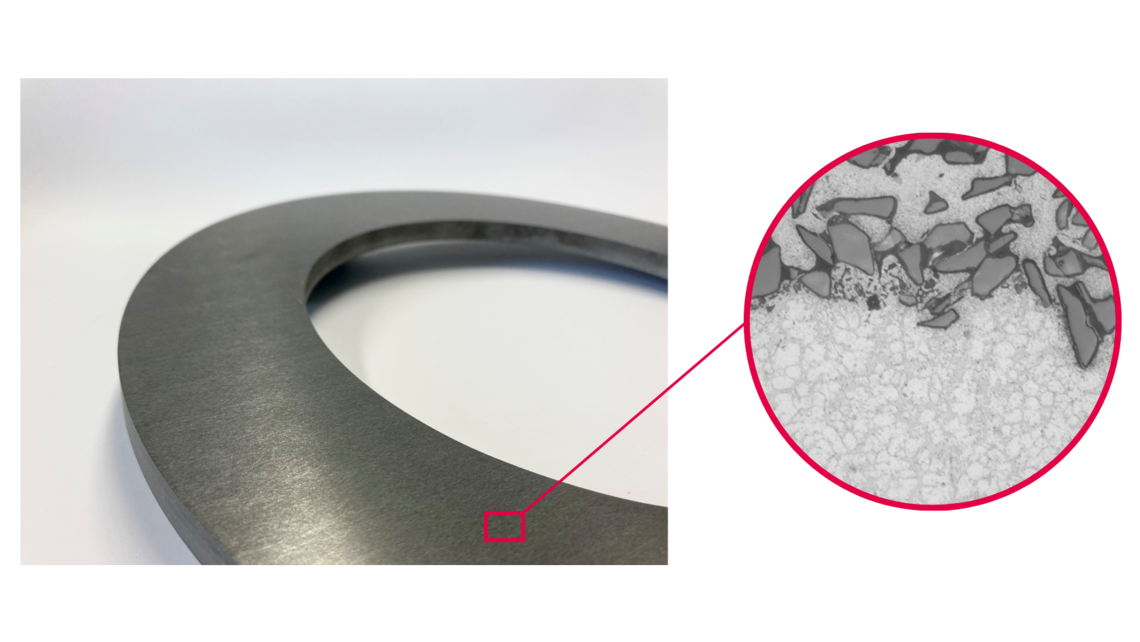

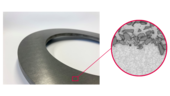

The highly porous ceramic preforms from CeramTec are infiltrated by the molten metal during the die casting of the MMC component. This creates a material-locking transition between metal-reinforced and ceramic-reinforced areas. Our preform technology opens up a wide range of new applications.

Preform Technology

CeramTec's MMC preforms are tailored to the needs of our customers and can be used with standard aluminium alloys.

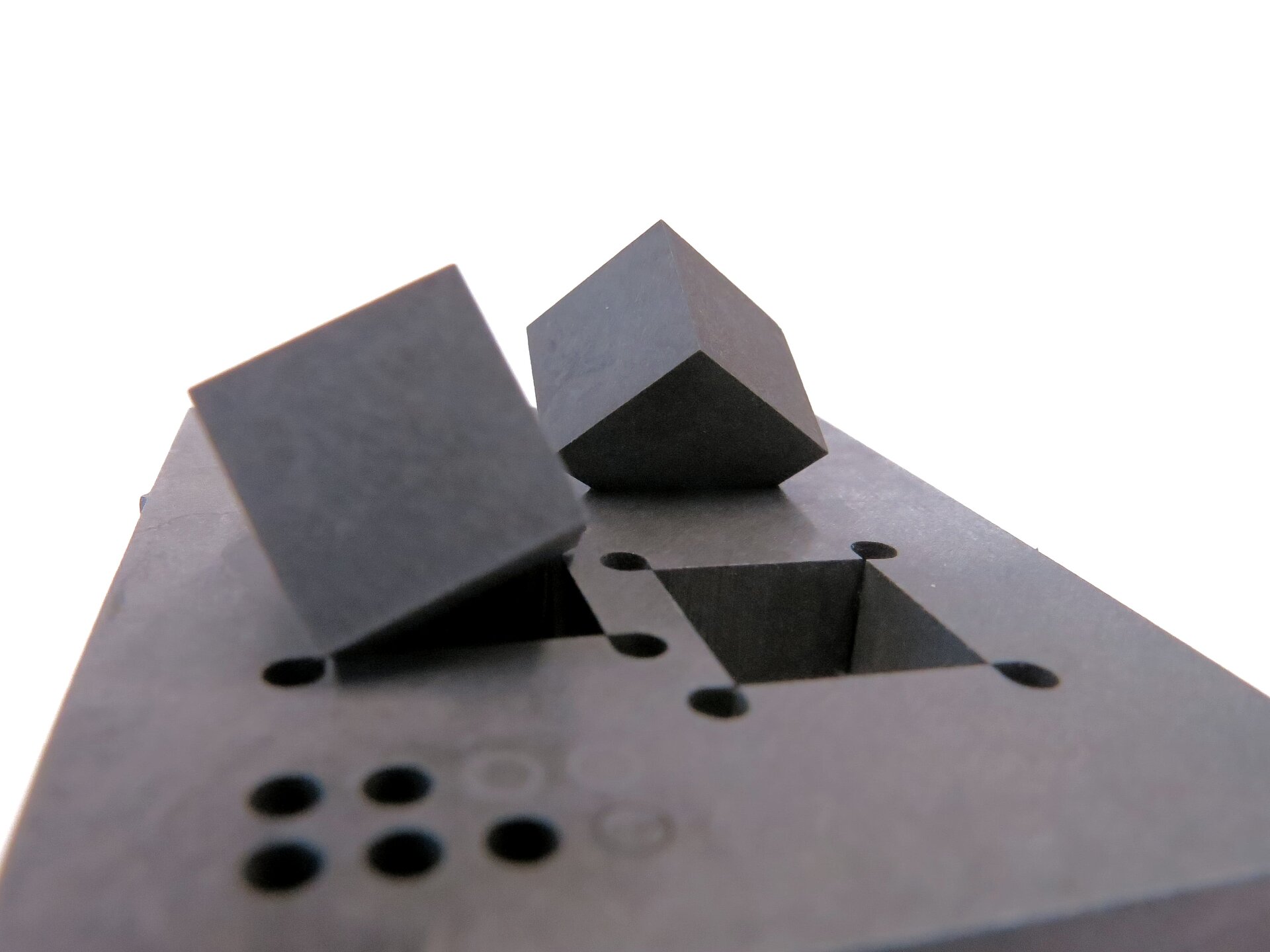

CeramTec offers a ceramic content of between 35 and 70%, whereby grain and pore sizes are equally adjustable. For high-performance products, an additional hardening additive can be used to further improve the properties. Diverse and complex geometries are possible with this manufacturing process.

A central element of our process is die casting, which is not only indispensable for infiltration and our process, but also enables the efficient production of larger quantities.

Our preform concept, combined with our tooling expertise, offers improved performance and lower total cost of ownership. Our preform portfolio includes a wide range of standard oxide and non-oxide ceramic materials.

Preforms made of silicon carbide and aluminium oxide

Silicon Carbide (SiC) Preforms

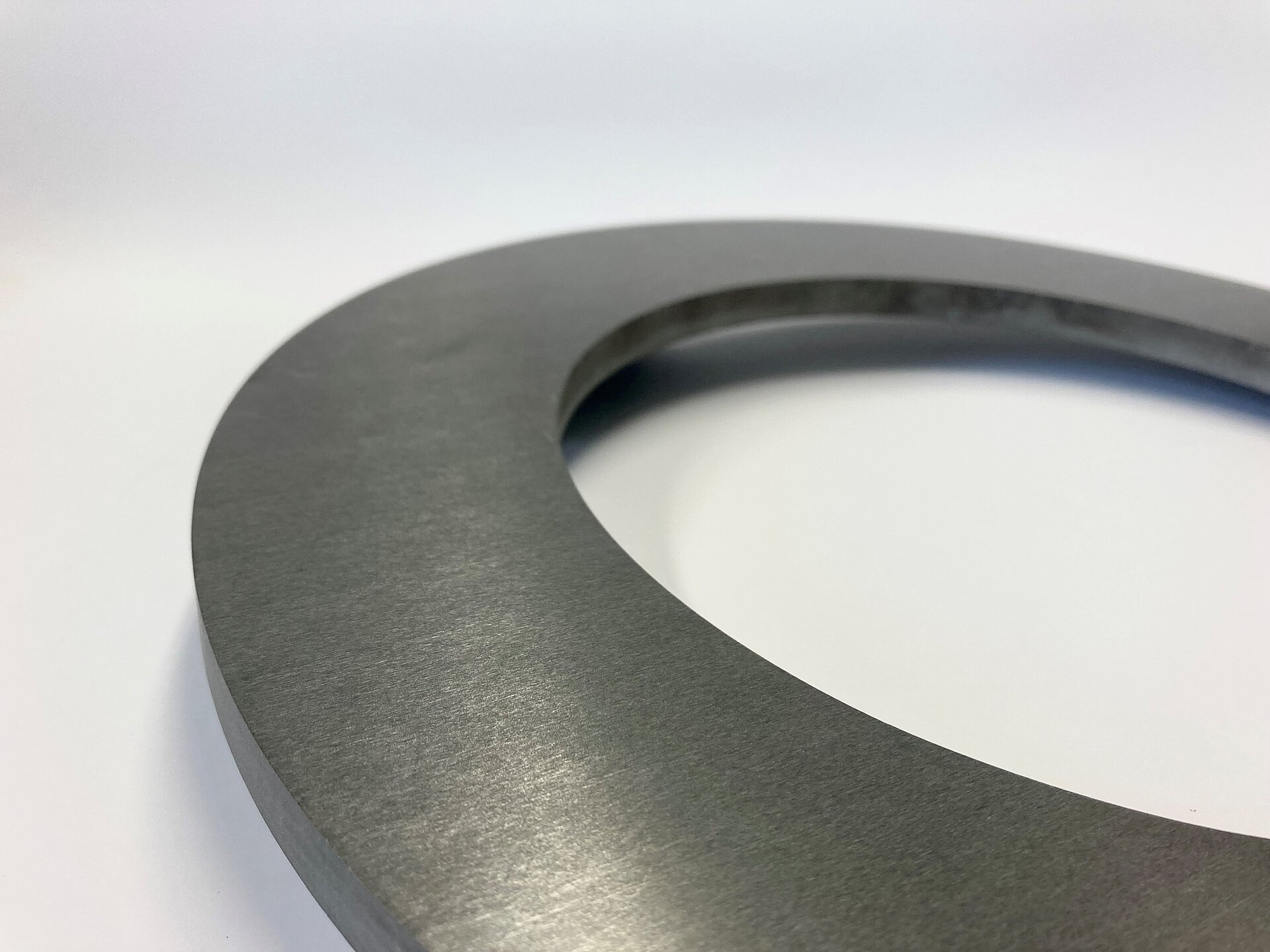

A SiC preform is perfectly suited for tribological optimisation. The use of a SiC preform offers higher thermal conductivity and improved abrasion resistance. One example of MMC components made of silicon carbide are brake discs. Due to the improved abrasion resistance, MMC brake discs generate less brake dust emissions, have a significantly longer service life and a weight reduction of around 50% compared to conventional grey cast iron discs.

Preforms aus Aluminium Oxide (Al2O3)

For applications with highly stressed mechanical components, an MMC made from an aluminium oxide preform is an excellent choice. This material has high flexural strength, an increased modulus of elasticity and good fracture toughness.

One example of MMC components with aluminium oxide reinforcement are stiffened subframes in vehicle structures or rotor brackets in electric motors. Local reinforcement with aluminium oxide MMC can reduce weight and installation space and significantly increase the rigidity and service life of the components. This enables lighter, more compact and at the same time more resilient designs - a decisive advantage for modern applications in e-mobility and vehicle construction.

E-Mobility

A typical area of application for aluminium oxide preforms in the field of e-mobility is the local reinforcement of housing and structural components, such as battery housings or motor mounts. The targeted insertion of ceramic-reinforced areas allows highly stressed zones to be mechanically stabilised without increasing the overall weight.

The MMC increases the modulus of elasticity and the strength of the component, which saves material on the one hand and reduces the overall weight on the other. This leads to a more efficient, lightweight design that meets the increasing demands on the performance and energy efficiency of electric motors.

Semiconductor Applications

In the semiconductor industry, the precision of components is crucial. Aluminium oxide MMC preforms are characterised by a coefficient of thermal expansion that is very close to that of the surrounding material.

This minimises thermal stresses during production and operation, as would occur with standard cast iron bearing bridges. The result is more stable components with greater dimensional accuracy and a longer service life, which is particularly important in high-precision, thermally stressed applications.

Machining

Increasing the proportion of ceramic particles in the MMC preform can pose a challenge for our customers' subsequent hard machining processes. One disadvantage of alternative manufacturing processes is that ceramic components have to be machined over a large area.

Our advantage: with CeramTec, the ceramic reinforcement is only applied locally, exactly where the preform was moulded in. This significantly reduces the amount of machining required, which saves time and money. Our expertise in the hard machining of ceramic materials and in the manufacture of ceramic cutting tools ensures that we can reliably support our customers throughout the entire production process.

CeramTec also develops cutting tools for MMCs and offers options with geometrically undefined cutting edges. We offer laser cutting for high precision requirements and water jet cutting for faster removal rates.