Thread Guides for the Textile Industry

By using technical ceramics for thread guides in the textile industry, high wear resistance and chemical resistance can be achieved, which leads to a longer service life of the thread guides and reduces the need for frequent replacement. In addition, the smooth surface of the ceramic enables precise thread guidance, resulting in improved quality of the textiles produced.

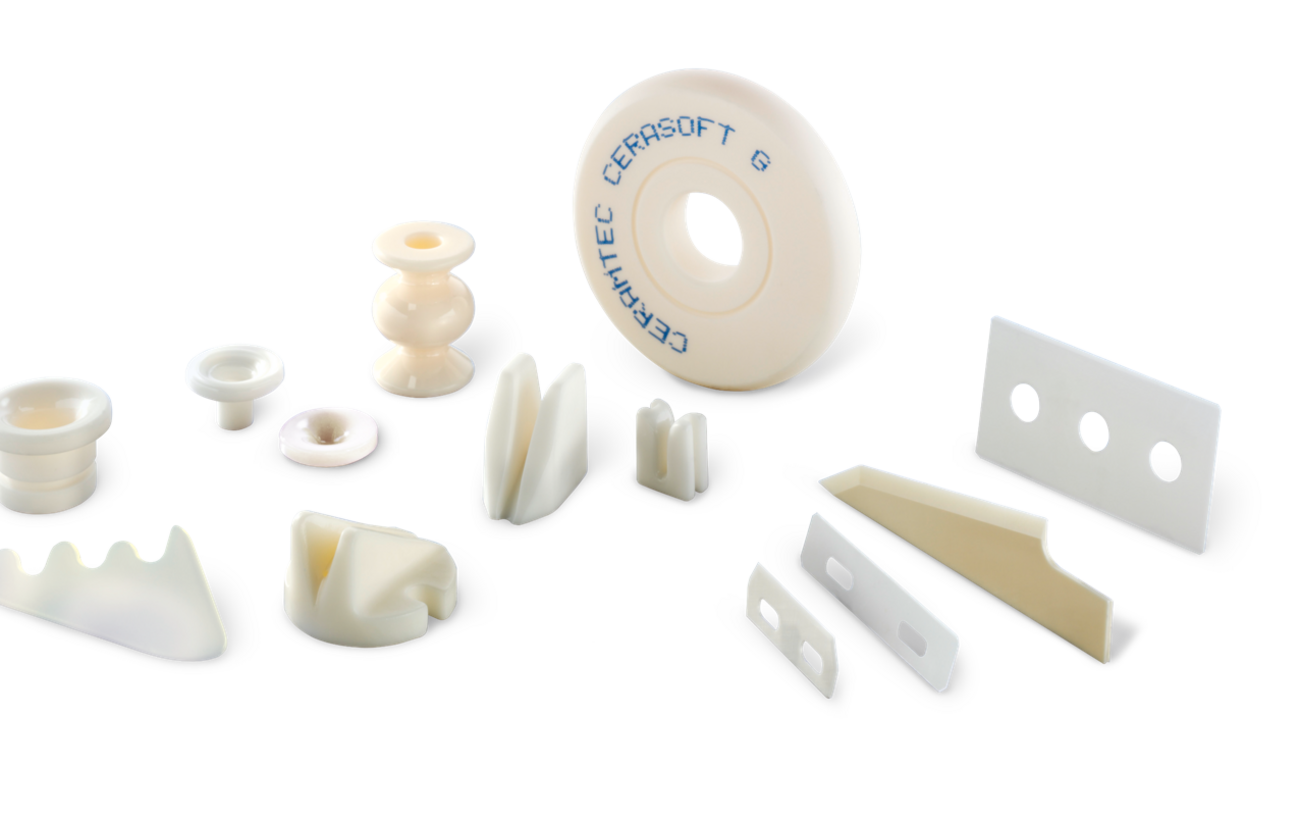

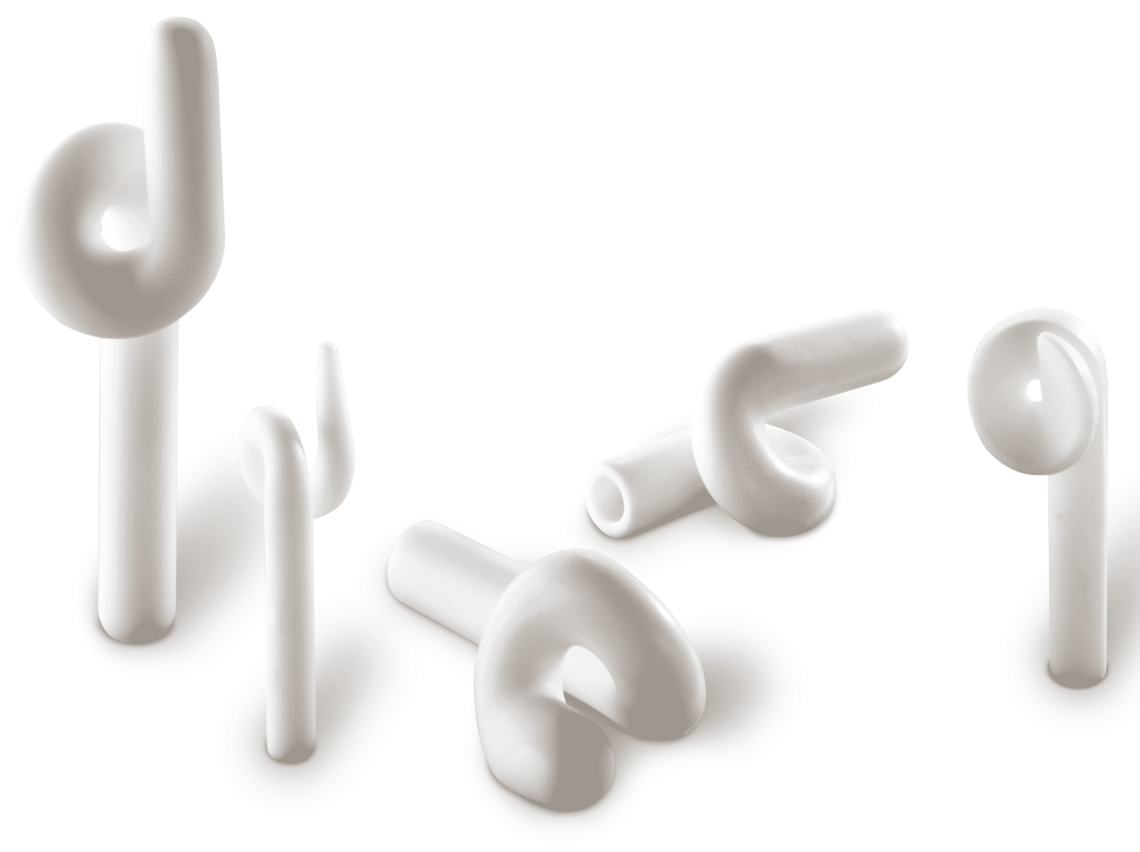

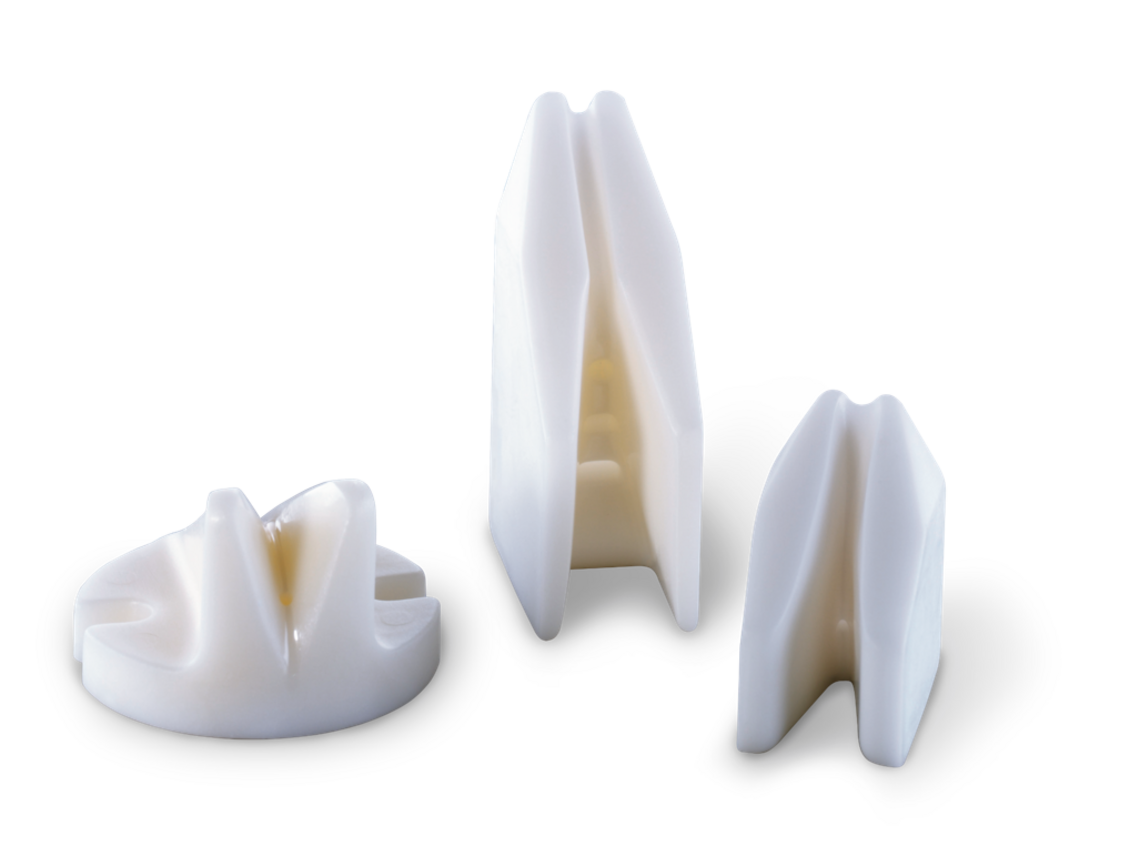

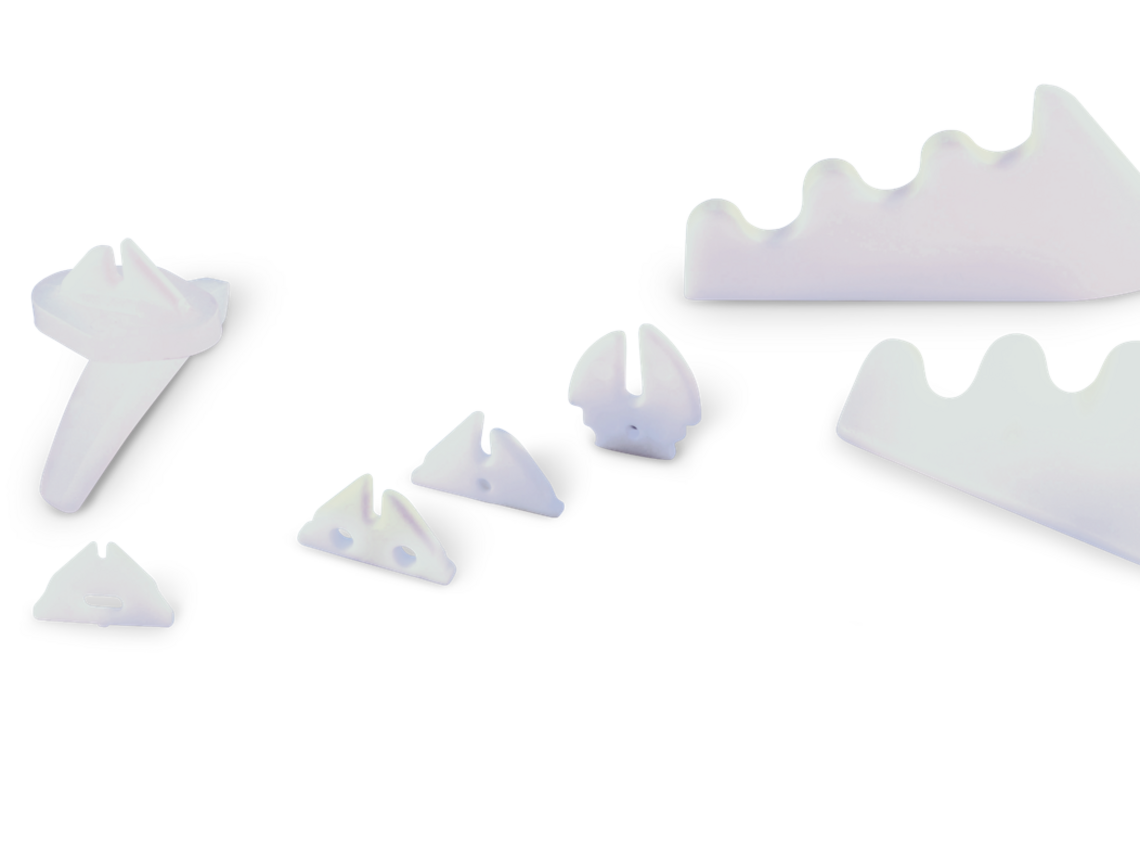

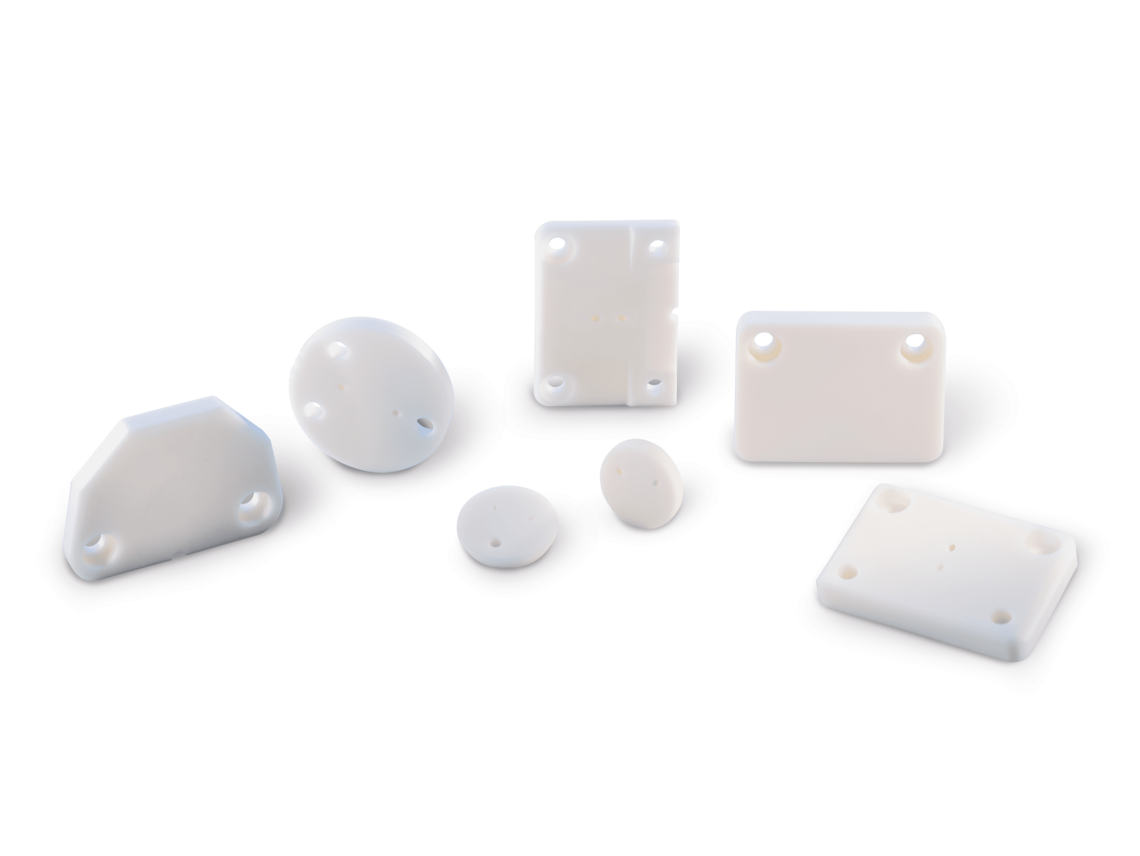

Our ceramic components for melt spinning, such as the purl tail yarn guides, preparation yarn guides, traversing yarn guides and interlacing nozzles, are used in the textile industry worldwide - as are our TRIBOFIL® and TRIBOSOFT surface qualities.

Polymer fibers are produced using a process known as polymer spinning, a special type of extrusion. In this production process a spinneret is used to form multiple, continuous filaments. There are four types of polymer spinning: Wet spinning, dry spinning, gel spinning and melt spinning. Melt spinning is used for meltable polymers. This is how a number of fibers such as nylon, olefin, polyester, saran and sulfar are produced.

Thermodynamics, friction, surface wear and electrostatic interaction during the production process have created the demand for ceramic components with high surface qualities such as those offered by CeramTec in material combinations designed especially for thread guides, yarn forming and yarn modification. CeramTec is one of the world’s largest producers of ceramic components for the melt spinning process (and filament spinning).

Melt Spinning Components made from Technical Ceramics:

- Pigtails

- Spin finish applicators

- Traverse guides

- Jet plates

- Oil Applicator Guides

Improved Surfaces for Thread Guides and Forming

In addition to “as-fired” and polished surfaces CeramTec also offers TRIBOFIL® and TRIBOSOFT for completely new surface dimensions:

TRIBOFIL® is a special surface for yarn guide elements in applications with low yarn tension and for processing conventional synthetic yarns without any damage whatsoever. This material has been proven in applications worldwide and textile industry experts appreciate its reliability.

TRIBOSOFT is also designed for use in processes at low yarn tensions without any yarn damage. This material is also characterized by long life cycles on both special yarns and raw materials containing aggressive additives such as spun-dyed yarns (SDY), spun-dyed black yarns, CS and bioactive yarns.