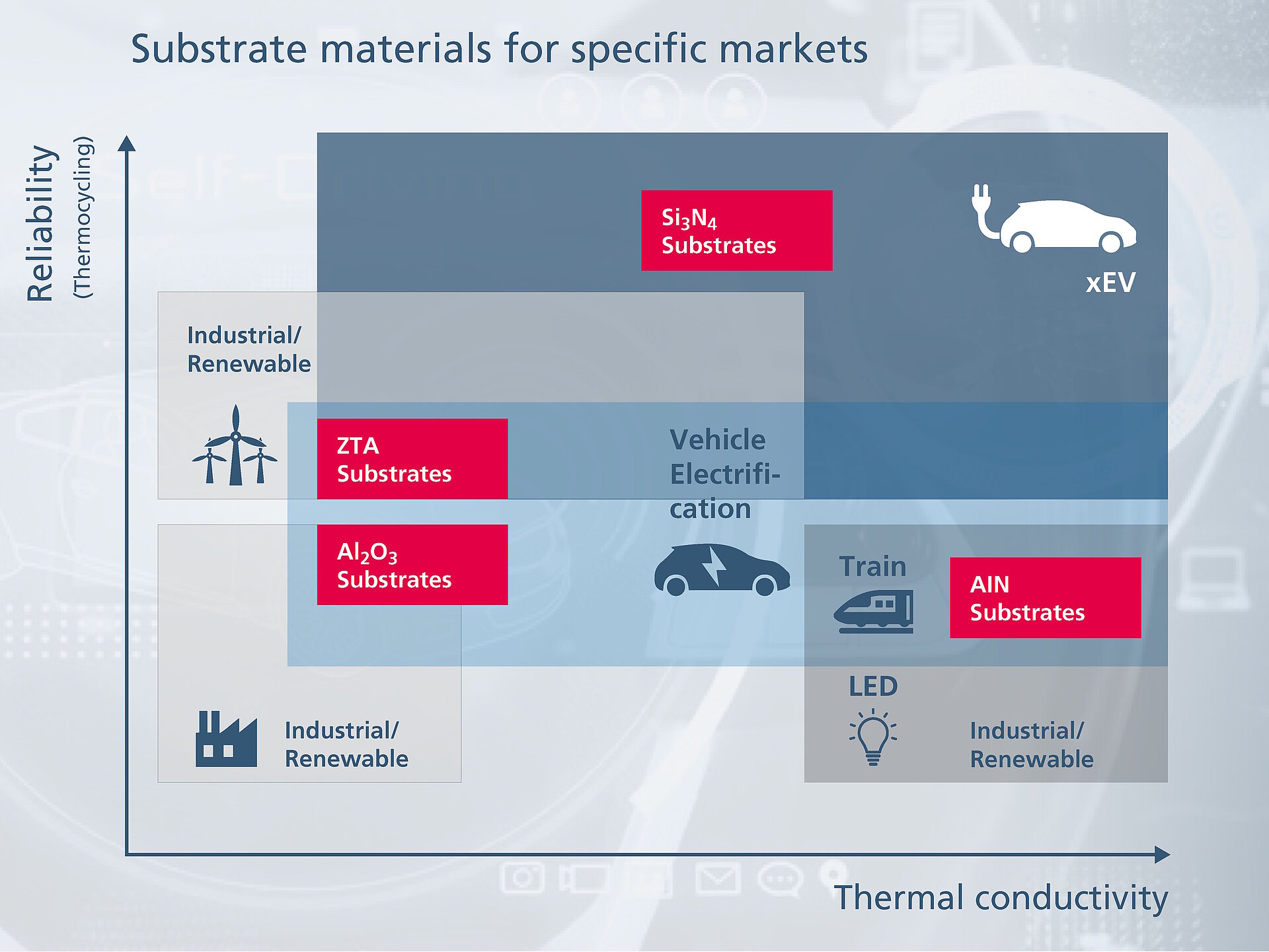

Silicon Nitride Substrates

New from 2024: Substrates made of silicon nitride for innovative applications in e-mobility. With its exceptional flexural strength of ≥ 700 MPa, it enables the use of very thick copper metallizations of up to 1 mm, even with a substrate thickness of just 0.25 mm. This remarkable property opens up new horizons for Active Metal Brazing (AMB) and Sputter Metal Bonding (SMB) applications that require robust and reliable performance.

Thanks to the ability to use copper with a thickness of 1 mm, silicon nitride offers excellent current carrying capacity and heat spreading. This is crucial for the development of compact power modules that require high power densities with limited external dimensions.

Furthermore, silicon nitride scores with a fracture toughness of ≥ 6.5 MPa√m, which is crucial for maximum reliability and longevity in applications such as battery-powered electric vehicles. The outstanding insulation and dielectric strength of ≥ 25 kV/mm AC/DC on thin Si3N4 substrates provides additional safety and enables the development of high power density power modules without compromising on safety.

Overall, CeramTec's silicon nitride is the ideal solution for e-mobility applications that require the highest performance, reliability and safety. Its exceptional robustness, combined with its outstanding flexural strength, fracture toughness and insulation resistance, makes it the first choice for the realization of high-performance and compact power components in the next generation of electric vehicles.

Technical Values & Parameters

Physical properties

- Density: ≥ 3.22 g/cm3

Surface properties

- Ra value: ≤ 0.4 µm

Mechanical properties

- Bending strength DR Sigma 0 (3 Point Method): ≥ 700 MPa

- Fracture toughness (IF Methode): ≥ 6.5 MPa*√m

- Young's modulus: ≥ 280 GPa

- Vickers hardness: not specified

Thermal properties

- CTE: 100-800°C: +/- 3.3 10-6/K

- Specific heat capacity at 25°C: ≥ 0.68 J/gK

- Thermal conductivity at 20°C: 90 W/m*K (+/- 10% measurement tolerances)

Electrical properties

- Dielectric constant at 1 MHz: +/- 7.8

- Dielectric loss factor at 1 MHz: ≤ 3 (10-3)

- Volume resistivity at 20 °C: ≥ 1014 Ω cm

- Dielectric strength: ≥ 25 kV/mm

Geometry

- Standard size: 5.5“ x 7.5“ (+ 0.2 mm/- 0.05 mm)

- Thickness: 0.25/0.32 (+/- 10%)

- Warpage/camber: 0.2 - 0.6 %

Substrates lasered

- Length and width tolerance: + 0.2 - 0.05 mm (+/- 0.1 % lasered)

- Thickness tolerance: +/-10%