Production and Processing of Ceramic Substrates

CeramTec production systems for manufacturing and processing ceramic substrates provide stamping, laser cutting, dry pressing and various methods of hard machining.

The substrate experts at CeramTec can recommend the most appropriate and economical production method based on the application area, material geometry and quantity.

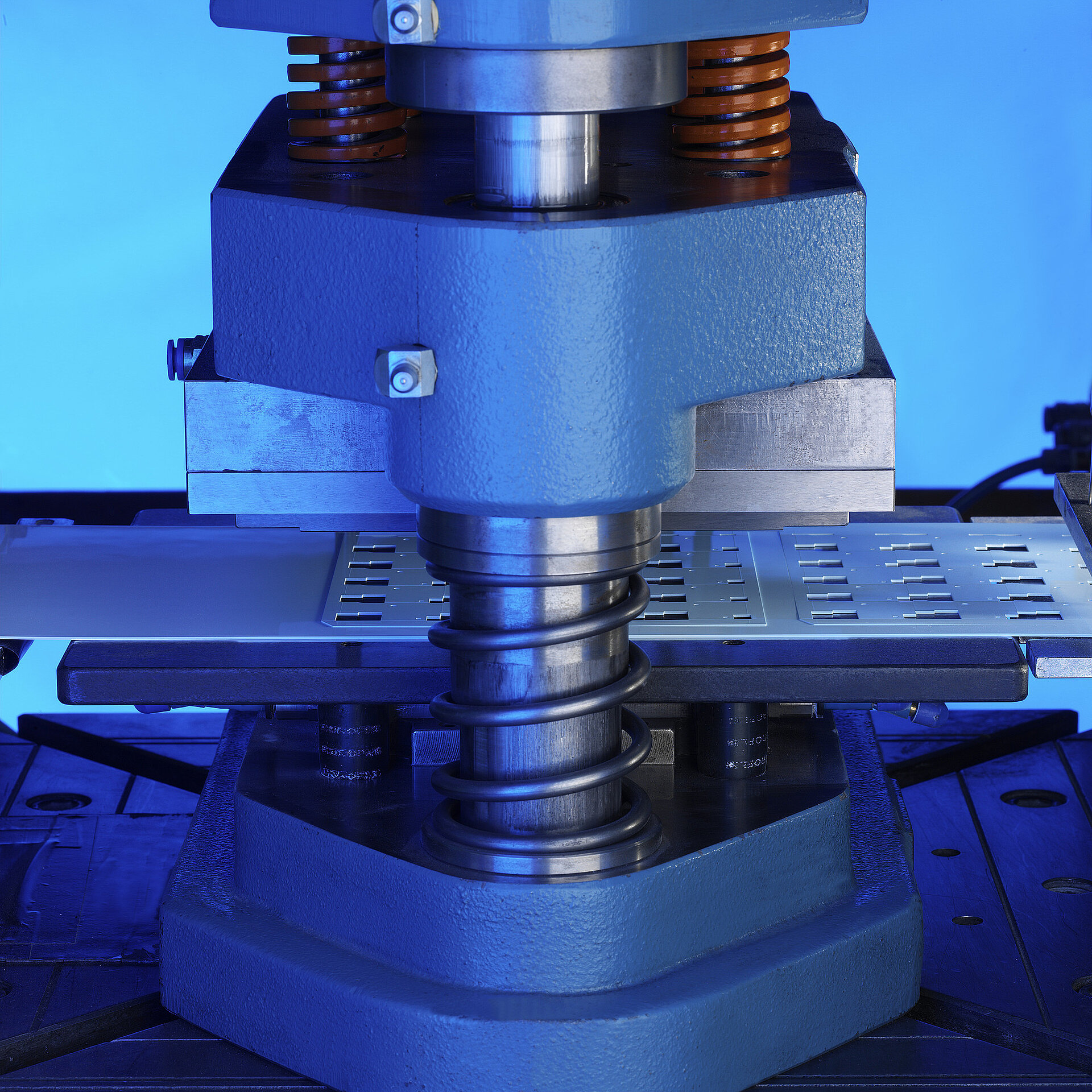

Stamped Substrates with Complex Geometries

Stamped substrates made from alumina and aluminum nitride can be manufactured in large-scale production series in standard formats or according to specific customer requirements.

They are characterized by their very even edges and can also be manufactured affordably in large series even with the most complex geometries and structures with through holes and vias, for single or multiple uses. Our substrates can be metalized on-site in our facilities after the stamping process.

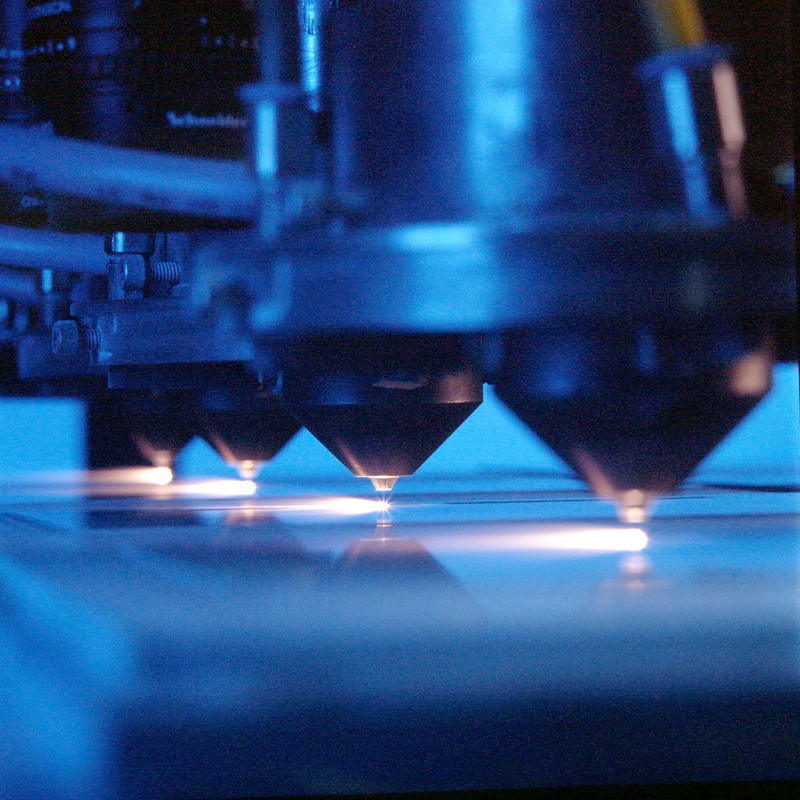

Lasered Substrates with the Tightest Tolerances

Lasered substrates can be delivered within 48 hours with the optional laser express service.

CeramTec has over 35 years of experience in lasering substrates and operates one of the largest laser facilities in the world. This allows the company to produce a wide range of external contour geometries, drill hole combinations, through holes and break lines without the need for time-consuming and costly tooling. Customers can also remotely transfer CAD data to us directly. For work with Al2O3 substrates computer-controlled CO2 lasers are used for scribing, cutting and drilling (smallest diameter: 0.15 mm) at very tight tolerances; for work with AlN substrates, CeramTec has access to Nd-Yag lasers.

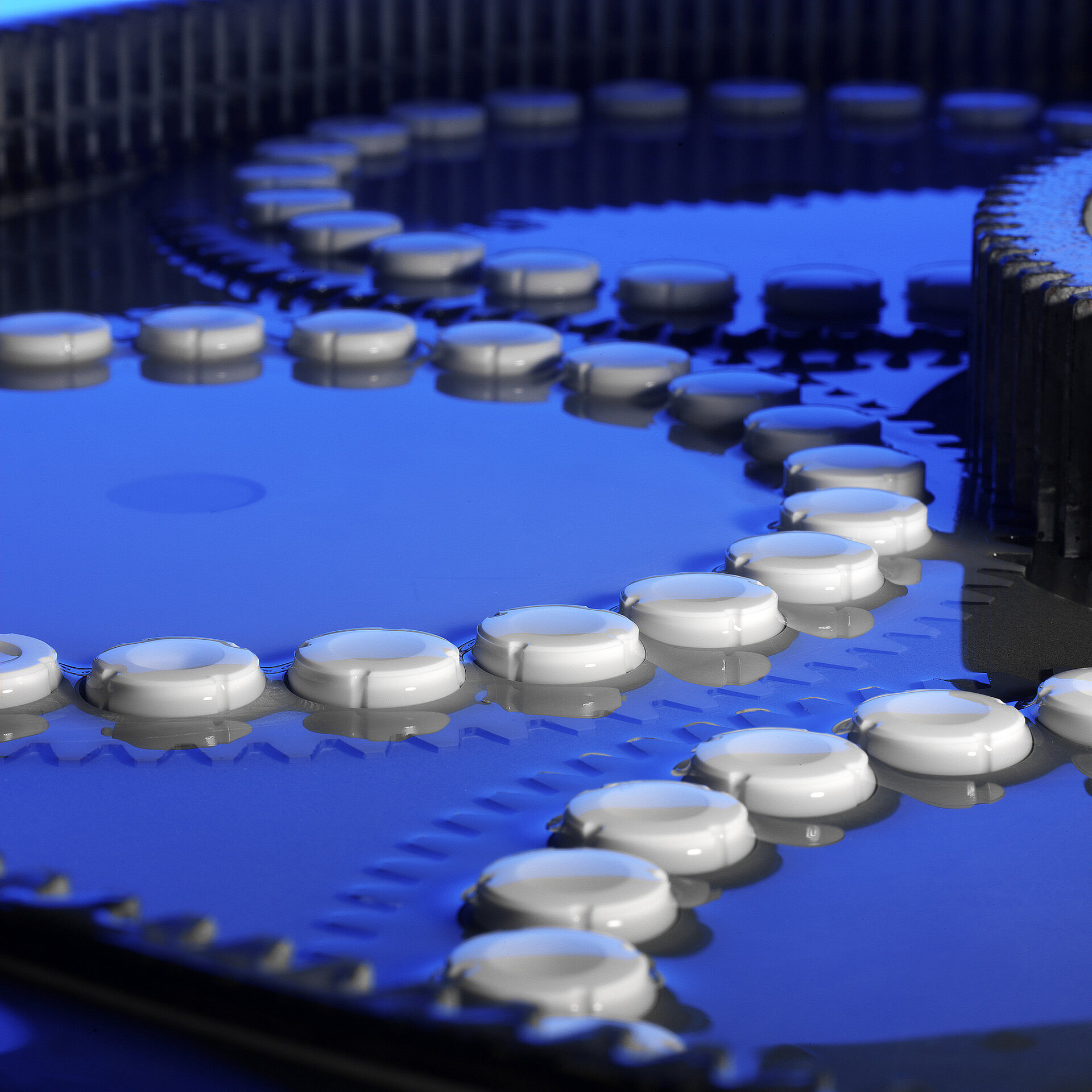

Dry-pressed Substrates in Large-scale Series Production

CeramTec manufactures dry-pressed substrates in large-scale series according to customer specifications in highly automated production lines with tools developed especially for this purpose. This method allows us to make substrates with irregular external contours, drill holes and break lines in nearly any thickness; we can even produce different thicknesses within a single substrate. The dry-pressing method makes it possible to manufacture substrates with highly complex geometries, through holes and blind holes from 0.2 mm in diameter.

Why Dry Pressing?

- Through holes, cavities, 3D

- Adjustable thickness

- Same shape – different thickness – all with a single tool

- Any thickness

- Large-scale series production

- No additional edge machining required

Hard Machining Substrates

A number of different hard machining methods and grades can be used on request to achieve extremely tight tolerances and improve edge finishes:

- Brushing

- Edge-perfect (lasered substrates)

- Edge-treated (lasered substrates)

- Lapping

- Polishing

- Sand blasting

- Grinding

CeramTec can also metalize any substrate following the hard machining process.