Ultrasonic Flow Meter Sensors

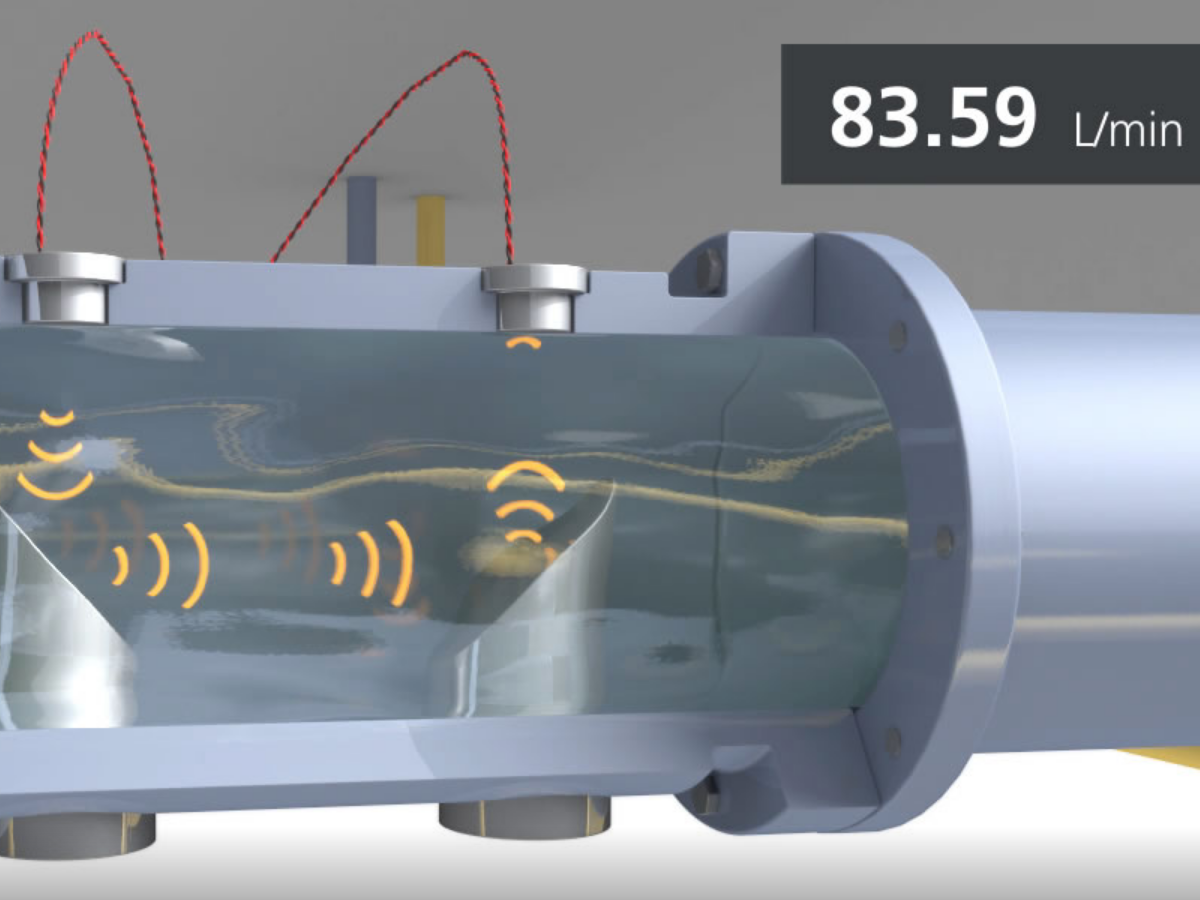

The use of this solid state ultrasonic technology eliminates the use of less reliable moving parts. This electrical method of measurement also lends itself particularly well for linking up with SMART meters which are being rolled out internationally largely backed by government regulation of utilities supplies.

Using our Piezoceramic materials, ultrasonic sensors with exceptional performance can be supplied for both gas and liquid flow measurement.

Gas Flow Measurement

For gas flow meter applications the design, selection and use of high quality matching layers is particularly important to ensure high sensitivity and optimal bandwidth. We offer a standard air coupled sensor ideally suited for this application.

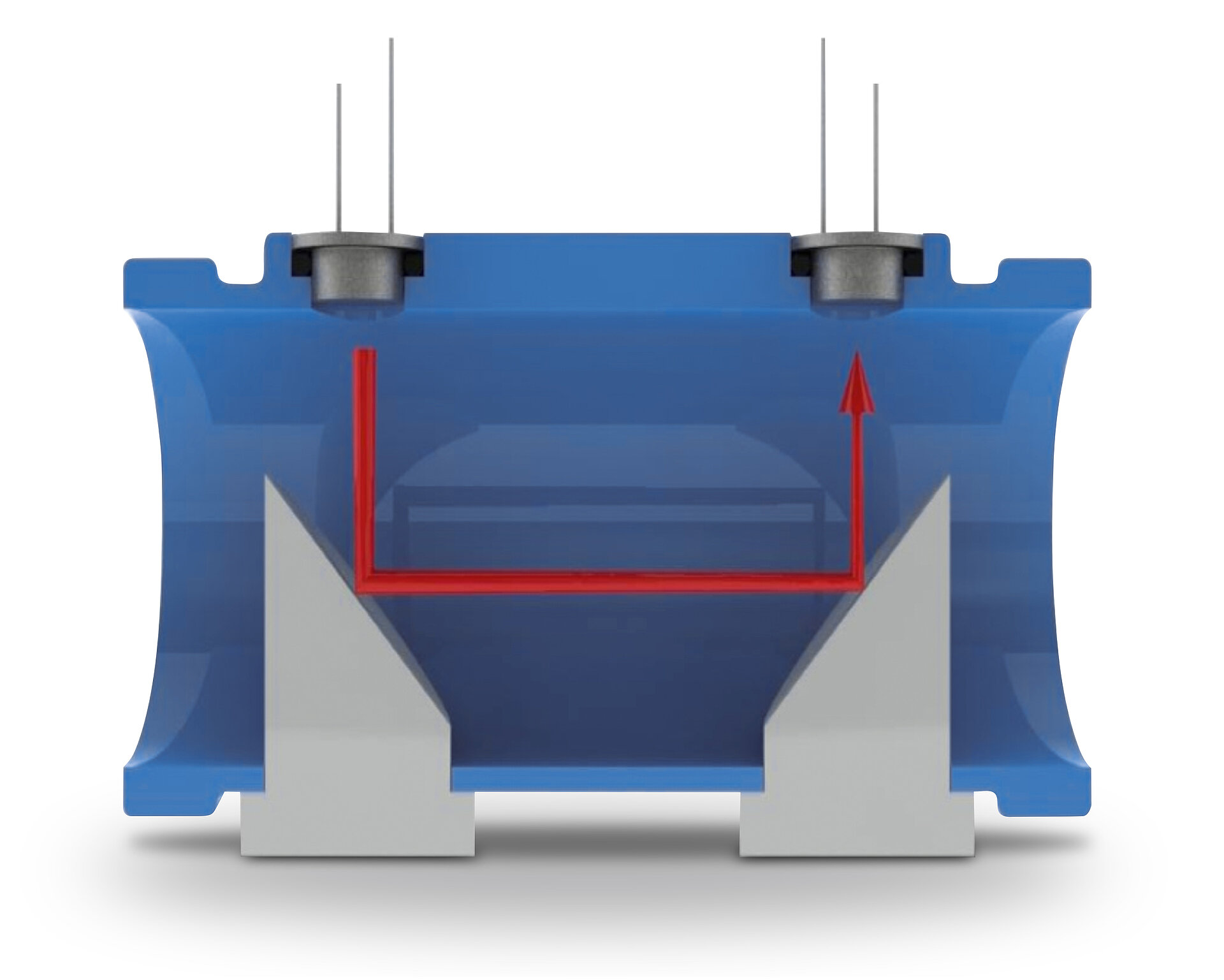

Water Flow Measurement

For liquid applications the design and manufacture of the sensor housing is particularly important to ensure the sensor is able to operate reliable under high pressure and within a wide range of temperatures. Our water coupled sensor is ideally suited for these applications. We can also offer a ceramic housed sensor that has improved thermal stability characteristics, particularly well-suited for operating up to 120°C.

Our in-house sensor test facilities are used to ensure we arrive at the best possible design solutions for our specific customer needs.

Our design team has recently extended its testing capabilities to include zero flow off set testing among beamwidth, bandwidth, impedance characteristics, temperature stability and burst pressure. This enables the team to be able to calculate this critical parameter before samples and parts are sent off to the customer. Knowing the zero flow offset during the design process allows CeramTec to design and select more accurate sensors which can give more precise measurements of flow. Our high level of testing for domestic flow metering ensures that we provide our customers with the highest possible quality flow sensors.