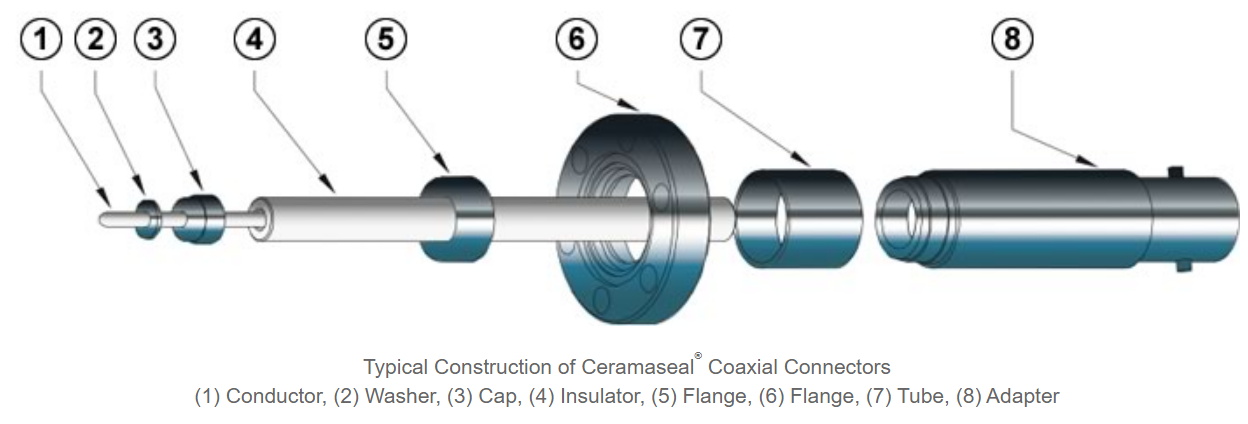

Ceramaseal® coaxial connectors consist of two concentric conductors: a central conductor surrounded by and insulated from a second tubular conductor. The outside conductor is usually at ground potential but in some product variations may be floated off ground by employing an additional insulating ring. The outer conducting surface can prevent radio frequency noise from passing to or from the central conductor.

CeramTec’s 50-Ohm matched impedance coaxial connectors are known throughout the industry for their superior performance in ultra-high vacuum and high-temperature applications. CeramTec has engineered special interfacing designs between the insulator and hardware to achieve low signal reflection at high frequencies.

Are you interested in our products & solutions?

Go directly to our online shop.

Ceramaseal® connectors are comprised of a hermetically brazed ceramic-to-metal assembly (receptacle) and mating plug. The receptacle is designed so that the overall stresses are minimized during the complex sealing process, thereby improving overall operating performance. 50-Ohm matched impedance connectors feature non-magnetic metals including gold-plated Inconel contacts and 304 stainless steel adapters.

All receptacles are made from high-purity, vacuum compatible materials. The insulators are made from high-strength, low-loss alumina ceramics that are metalized using the refractory-metal sintering process. The hardware is primarily stainless steel or nickel-iron alloys, but conductor materials may vary according to design. The assemblies are brazed together using copper, gold-copper and silver-copper alloys.

Coaxial Connector standard specifications

- Grounded shield or floating shield configuration

- High frequency 50 Ω impedance matched connectors as SMA, BNC, Type N and HN

- Connectors sold with or without air side plugs

Custom designs and solutions

- Multiple coaxial and multipin connectors in a flange

- Double ended 50 Ω coaxial connector with floating shield for cryogenic applications

- Coaxial connectors using a glass-ceramic seal for cryogenic and caustic environments

- LC connector and other military style coaxial connectors

CeramTec uses advanced techniques and methods to control critical processes, including 100 percent helium leak testing and x-ray measurements for metalization control.

Standard installation mountings for Ceramaseal® coaxial connectors include:

- Welding (pulse-TIG, TIG, laser, E-beam welding)

- ISO KF flange

- ConFlat flange

- NPT fitting

- 1" baseplate

| Category | Classification | V (DC) | Coupling | A | Cabel |

| Subminiature | Microdot | 1.000 V | Threaded | 2 | 0,08 Æ, 50 W |

| SMB (Subminiature-B) | 375 V | Push-on | 1,4 | RG-174/U | |

| SMA (Subminiature-A) | 500 V | Threaded | 0,8 – 1,8 | RG-58/U | |

| Miniature | BNC | 500 V | Bayonet | 3,6 – 4,4 | RG-58/U |

| MHV (Min. High-Voltage) | 5.000 V | Bayonet | 3,6 | RG-59/U | |

| SHV-5KV (Safe High-Voltage) | 5.000 V | Bayonet | 10 | RG-59/U | |

| SHV-10KV (Safe High-Voltage) | 10.000 V | Bayonet | 2,2 - 10 | RG-58/U | |

| SHV-20KV (Safe High-Voltage) | 20.000 V | Bayonet | 16,5 | RG-213/U | |

| BSHV (Bakeable Safe High-Voltage) | 7.500 V | Threaded | 8 | RG-59/U | |

| Medium | N | 1.500 V | Threaded | 0,8 – 5 | RG-8/U RG-9/U RG-10/U |

| NH | 7.000 V | Threaded | 7 | RG-8/U RG-9/U RG-87/U RG-213/U RG-214/U RG-225/U |

Available Connector Types

MHV (Miniature High-Voltage) Connectors

Are designed for high voltage applications of BNC connectors (DC voltage between 500 V and 5 kV). MHV connectors are sometimes referred to as “high-voltage BNCs”. CeramTec’s standard MHV connectors are available as single ended or double ended units with a floating shield or a grounded shield.

SMA (Subminiature Type A) Connectors

Offer a threaded interface in a subminiature size. Matched impedance designs are also available and are ideally suited for high frequency signal transmission. CeramTec’s standard SMA connectors are available as single ended or double ended units.

SMB (Subminiature Type B) Connectors

Designed for quick connecting and disconnecting. This is made possible by the SMB’s spring retention connector. CeramTec’s standard SMB connectors are single ended and available with a grounded shield or a floating shield configuration.

BNC Connectors

Are the most popular miniature-sized connector and can accommodate up to 500 V DC. BNC connectors are characterized by their quick connect/disconnect bayonet coupling. Matched impedance designs are also available and are ideally suited for high frequency signal transmission. CeramTec’s standard BNC connectors are available as single or double ended units with a grounded shield or a floating shield.

Type N Connectors

Are the most popular medium-sized connectors, accommodating voltages up to 1.5 kV. The threaded coupling provides low noise and increases resistance to shock and vibration. Matched impedance designs are also available and are ideally suited for high frequency signal transmission. CeramTec’s standard Type N connectors are available as single or double ended units.

Microdot Connectors

Are the smallest standard threaded interface connectors CeramTec offers for use in ultra-high vacuum (UHV) environments. CeramTec’s standard Microdot connectors are available as single ended or double ended units.

SHV (Safe High-Voltage) Connectors

Feature an improved interface over MHV connectors. The SHV outer contact ground connection is maintained through the center contact mating cycle. The center contact is recessed to prevent shock hazard when disengaged. Four designs are included in this Product Guide covering DC voltages from 5 kV to as high as 20 kV. The BSHV version is a bakeable SHV connector that exhibits the safety level of the SHV. CeramTec’s standard SHV connectors are single ended and available with a grounded shield or a floating shield (SHV 5 kV) configuration.

HN Connectors

Are Type N series connectors that have been designed to take higher voltages (up to 7 kV). These matched impedance designs are ideally suited for high frequency signal transmission.