Alumina 3D Printing with Add-On Effect

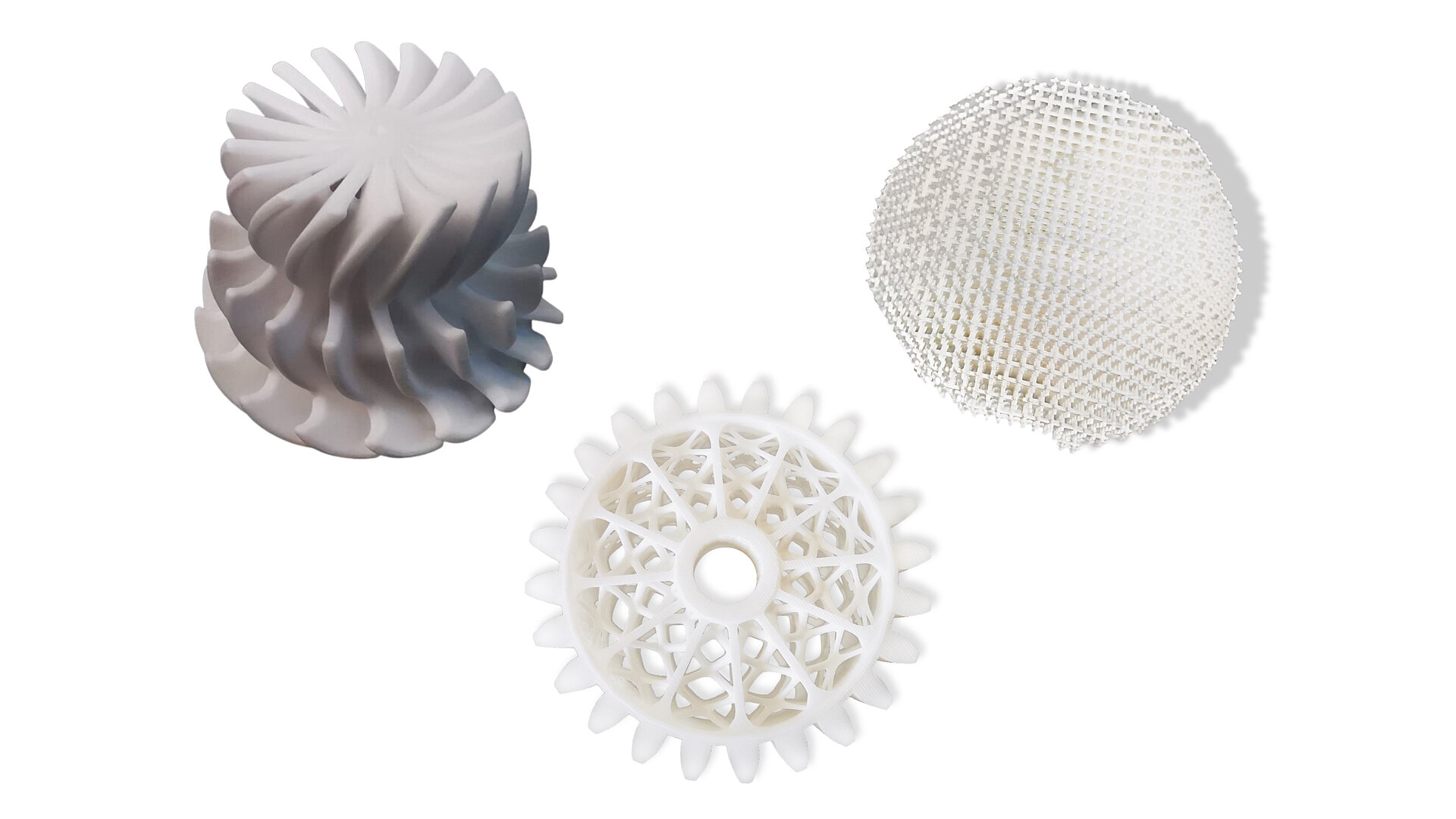

Our alumina 3D printing solutions combine innovative material jetting technology with outstanding material properties.

This additive manufacturing process drops liquids with ceramic nanoparticles to build objects layer by layer. Print heads with thousands of inkjet nozzles that simultaneously jet millions of tiny drops of building and support materials allow objects to be created with micrometre precision into reality. This unique capability, along with proven material advantages such as electrical insulation, strength, corrosion and wear resistance, enables the design and manufacture of tiny and highly complex custom components for a wide range of applications such as the production of medical device manufacturing, metrological instruments, fine mechanics and many more.

Collaboration: In November 2022, it was announced that we are collaborating with XJet, an Israel-based provider of industry-leading additive manufacturing solutions. Read the XJet press release