SiAlON – Silicon Alumina Nitride

α/β SiAlON ceramics are some of the newest materials found in technical ceramics and are related to silicon nitrides. They occur only in certain raw material compositions and consist of at least the three phases α-SiAlON, β-SiAlON and an amorphous or partially crystalline grain boundary phase.

The material class of α/β-SiAlONs is characterized by the unique combination of even higher hardness than normal silicon nitride with the same high level of toughness. The α-SiAlON phase is very hard, while the β-SiAlON phase – like normal silicon nitride – exhibits a high level of fracture toughness. The phase fractions of α-SiAlON, β-SiAlON and the grain boundary phase can be adjusted in wide ranges, which makes it possible to adapt the material properties of α/β-SiAlON to meet the requirements profiles of different applications.

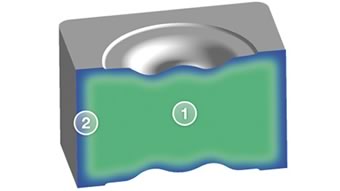

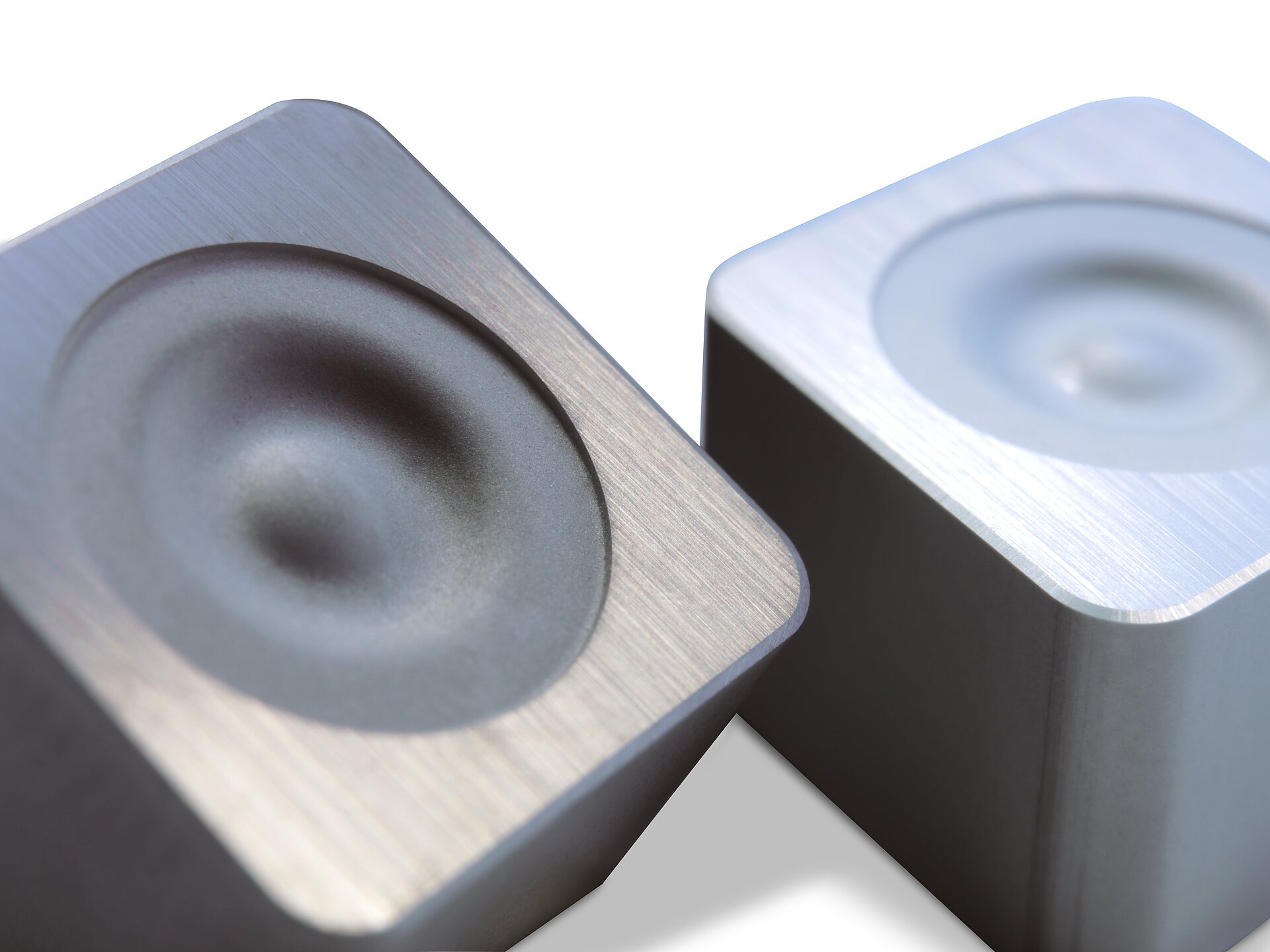

Under special conditions it is even possible to produce a gradient material that contains a higher fraction of α-SiAlON on the surface than in the interior. CeramTec takes advantage of this, for example, in several highly wear-resistance cutting ceramics for machining applications: The gradient in the α-SiAlON fraction gives the surface of an indexable insert higher hardness than the core, which greatly increases the wear resistance of the ceramic cutting material. The fracture toughness in the interior remains high.

The hardness and wear resistance of α/β-SiAlONs can be increased even further by incorporating hard materials such as silicon carbide. This material variation of silicon alumina nitrides has proven itself in components exposed to high tribological stress, for example in the paper industry.