Dielectric Ceramic Materials

Dielectric ceramic materials are used for our range of high voltage capacitors because of their capability to support electrical fields and/or to act as insulators. We prepare our own dielectrics from raw materials at our Ruabon manufacturing site with Dielectric Constants from 6 to 5000 which allows us to design and manufacture capacitors from 5 to 10,000pF in voltage ranges from 5kV to 50 kV.

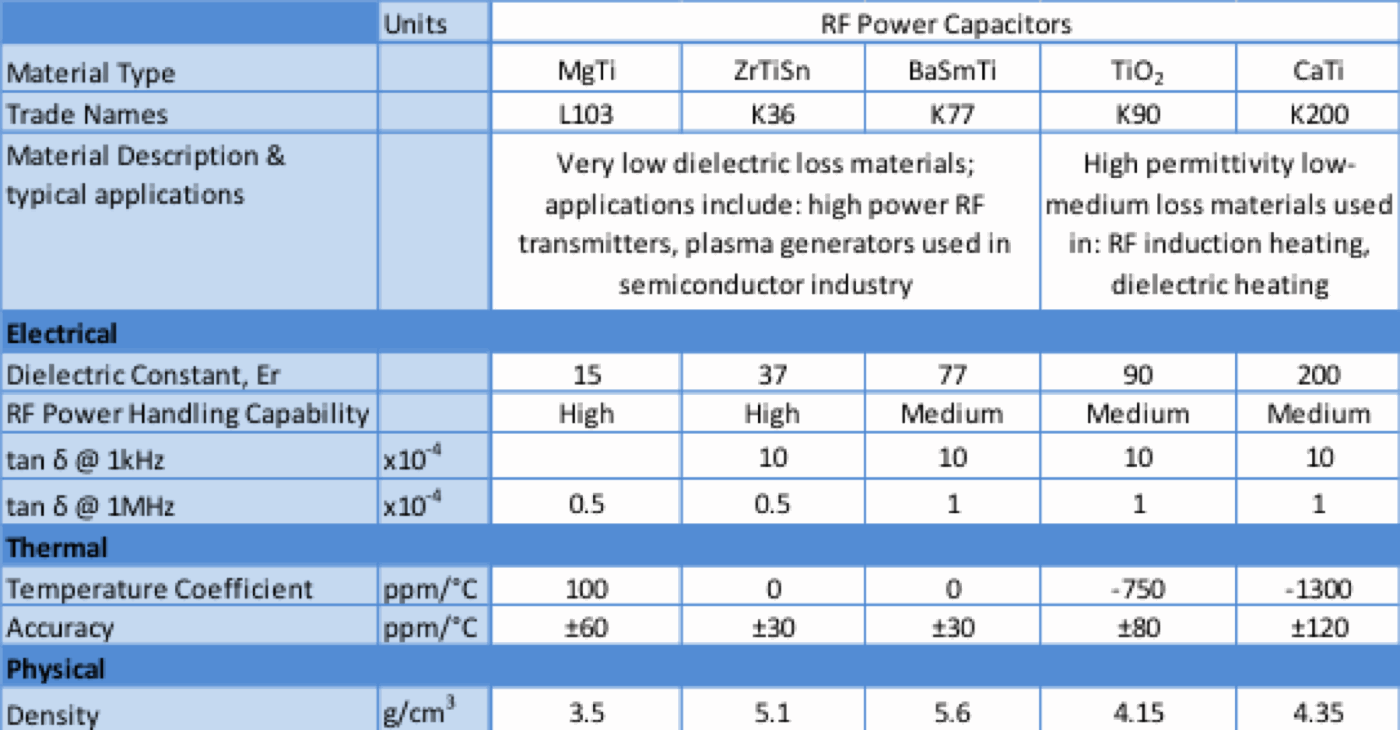

Our capacitor products cover two broad application areas, RF power and high voltage. Each of these product lines requires particular ceramic material formulations for optimal performance.

The RF power capacitors are produced from our dielectric ceramic materials exhibiting low dissipation factor, stable properties and excellent breakdown field strength. These are normally identified as class 1 types and can be found, for example, in broadcast transmission equipment.

High voltage capacitors use materials with high dielectric constant and therefore excellent volumetric efficiency. These are normally identified as Class 2 types and can be found in various applications including live line indication in electricity distribution networks and X-ray imaging power supplies.

They do not have the low dissipation factors and stability with voltage and temperature associated with Class 1 capacitors and it should be noted that the capacitance will decrease over time for many of these materials. The ageing rate is normally quoted as a % per decade hour and for products the stated capacitance specification is associated with a defined period of time.

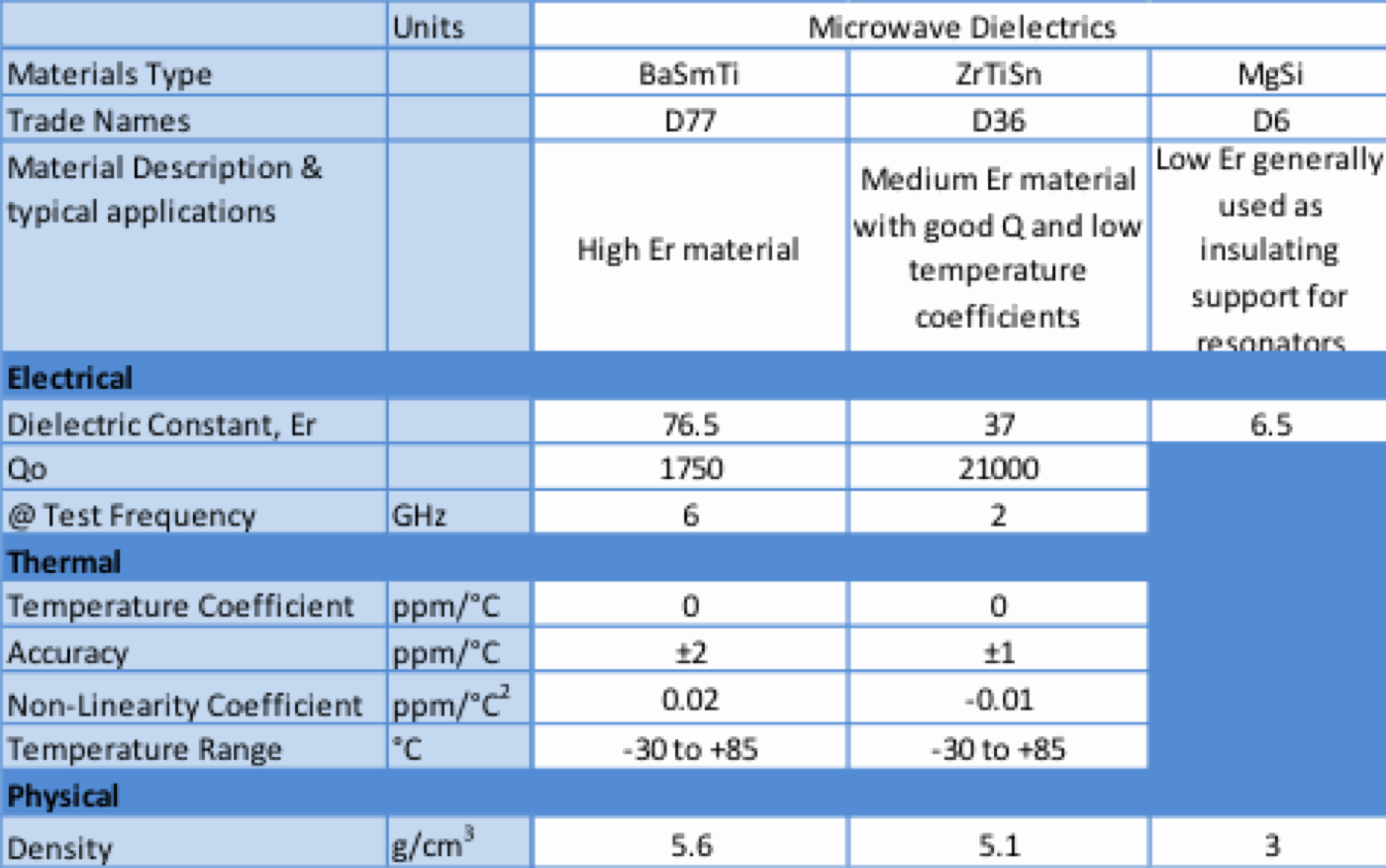

We also produce our own dielectric ceramics for niche resonator or filter applications at frequencies from 50MHz to 15GHz. These deliver high Q and very low temperature coefficient of frequency on a consistent basis. The D36 material has very low magnetic susceptibility making it ideal for use in medical imaging and therapy applications where non-magnetic components are required.