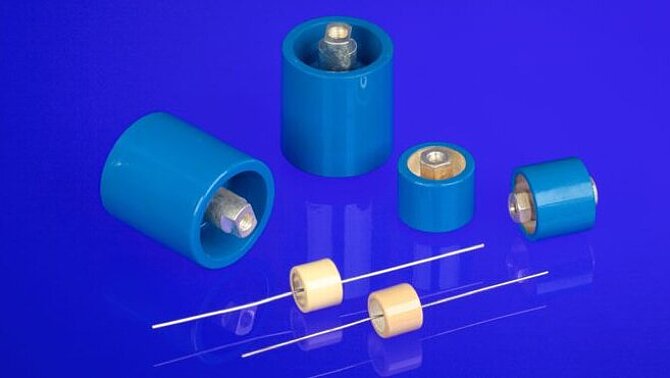

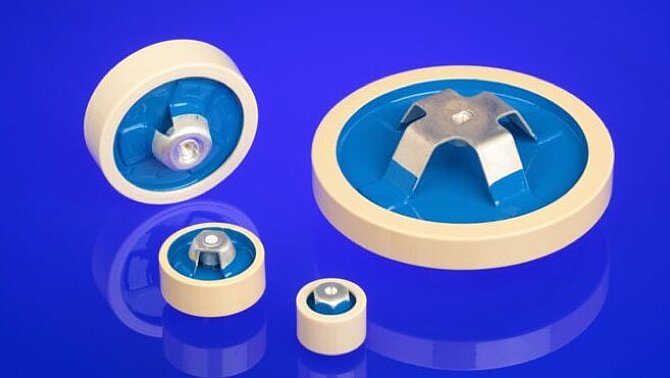

RF Ceramic Capacitors

RF power capacitors are produced from our dielectric ceramic materials exhibiting low dissipation factor, stable properties and excellent breakdown field strength. These are normally identified as class 1 types and can be found, for example, in broadcast transmission equipment, semiconductor plasma processing, induction heating and also in mass spectroscopy systems.

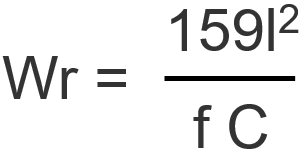

Rated current Ir is the r.m.s. current for which the capacitor is designed.

Rated reactive power Wr is such that the capacitor temperature rise shall not exceed 45°C when operated, in still air, at an ambient temperature of 30°C (or as otherwise specified in the datasheet).

Frequency

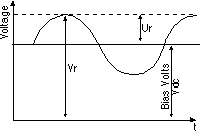

When a capacitor is subjected to an RF load, heat is generated in the dielectric due to internal losses and in the electrode system due to resistance heating.

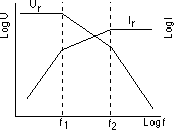

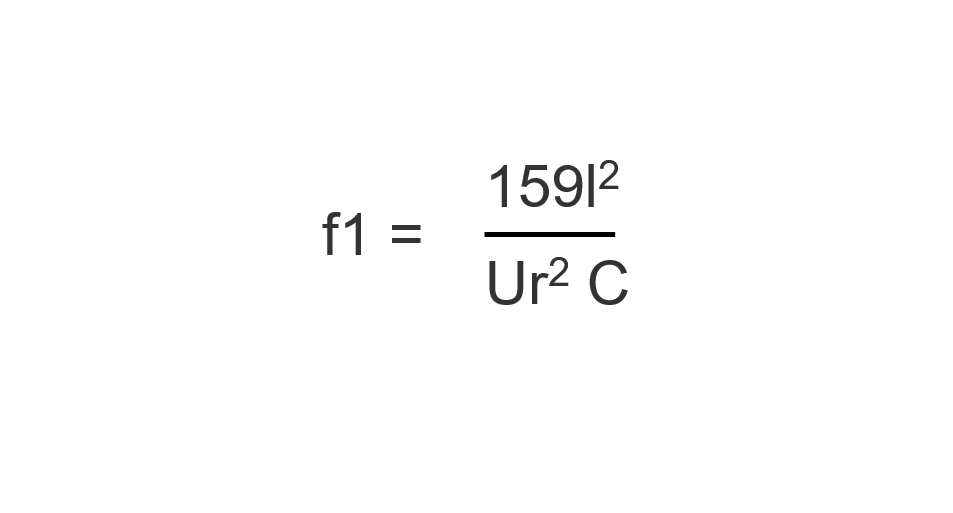

The performance is characterised by a typical frequency load curve as shown below:

Operating Conditions

In certain circumstances such as intermittent operation the reactive power and current ratings can be exceeded but in no case should the maximum body temperature of the capacitor be exceeded normally 95°C or as otherwise stated in the data sheet.

For guidance short term power ratings and current ratings of 1.5 x are permissible. The voltage ratings must not be exceeded.

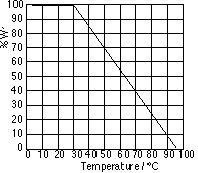

If the capacitors are operated in an ambient temperature higher than 30°C then the reactive power rating must be reduced as shown in the graph.

The user should ensure that the permissible operating conditions for the capacitor are not exceeded.

Care should be taken in the mechanical mounting to ensure that mechanical / thermal stresses are minimised. Vertical mounting recommended.

The use of forced cooling methods allows higher reactive powers to be applied provided that the maximum temperature of the capacitor is not exceeded. Methods of cooling commonly used are:

- Forced air cooling

- Water cooled connections

- Oil immersion