Shapes and Mechanical Tolerances

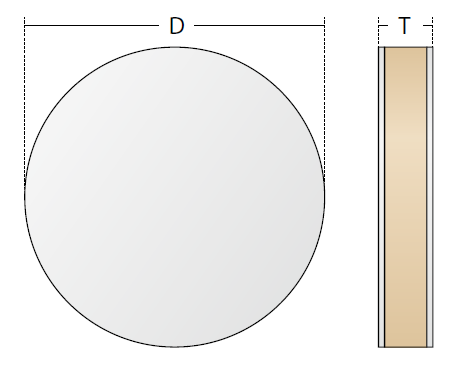

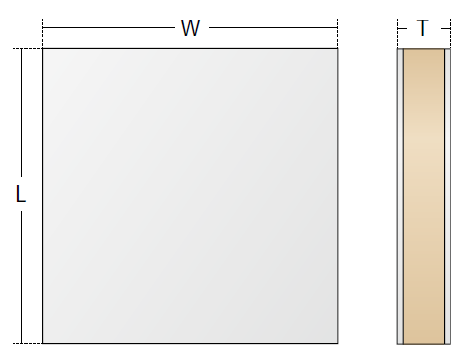

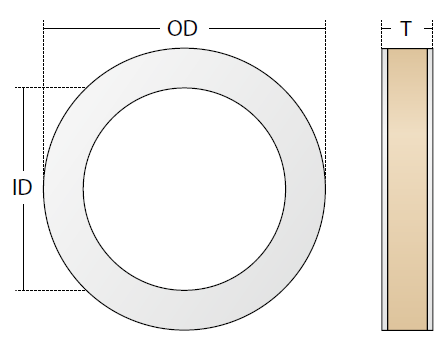

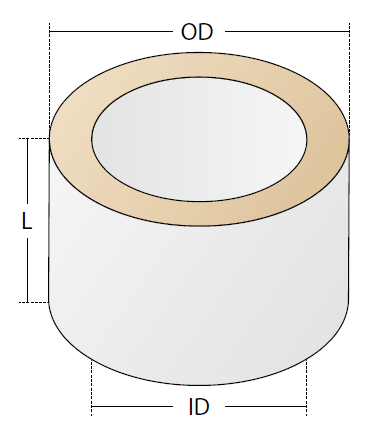

In addition to the shapes shown, custom shapes are also available. Parts can be made to the size ranges shown, but not in every combination of thickness and lateral dimensions. A separate list of standard sizes of parts available can be obtained on request.

Standard Mechanical Tolerances

Tolerances on machined dimensions apply to most components. For large size parts, confirmation of the tolerances achievable will need to be agreed prior to placing an order. Components can be produced to tighter tolerances (e.g. Concentricity within 0.13mm (0.005”) TIR and surface finish (Ra) within 1.6μm (62μin)).

Care should be taken not to over-specify a tolerance as this can significantly increase costs. Discover more

Discover more information, applications & features: Piezoelectric Discs

Discover more information, applications & features: Piezoelectric Plates

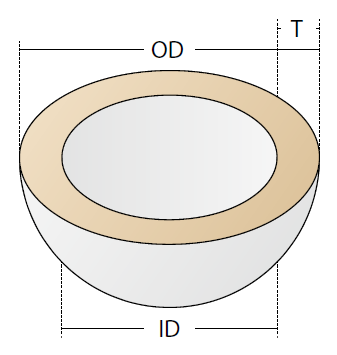

Discover more information, applications & features: Piezoelectric Rings

Discover more information, applications & features: Piezoelectric Tubes

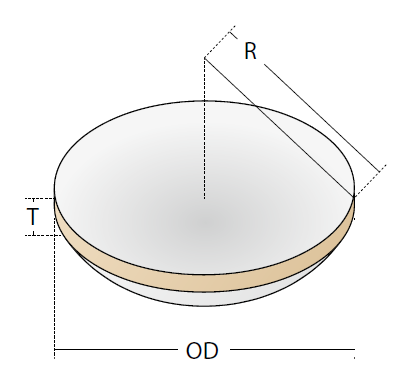

Discover more information, applications & features: Piezoelectric Hemispheres

Standard Mechanical Tolerances

| Outside diameter | ±0.15 mm |

| Inner diameter | ±0.15 mm |

| Length & width | ±0.15 mm |

| Thickness | ±0.05 mm |

| Squareness (edge to face) | Within 0.15° |

| Concentricity | 0.2 mm TIR |

| Surface flatness (lapped parts) | 12 μm (0.012 mm) |

| Surface flatness (large sliced parts) | 15 μm (0.015 mm) |

| Parallelism (lapped parts) | 12 μm (0.012 mm) |

| Parallelism (large sliced parts) | 60 μm (0.06 mm) |

| Surface finish (Ra) | 3 μm (0.003 mm) |